Development of energy-saving frying production line

Energy-saving, almost all the direction of industry efforts, the equipment industry is no exception. The industry believes that the food processing industry, to ensure the stability of the production line is to achieve the basic conditions for energy saving and environmental protection.

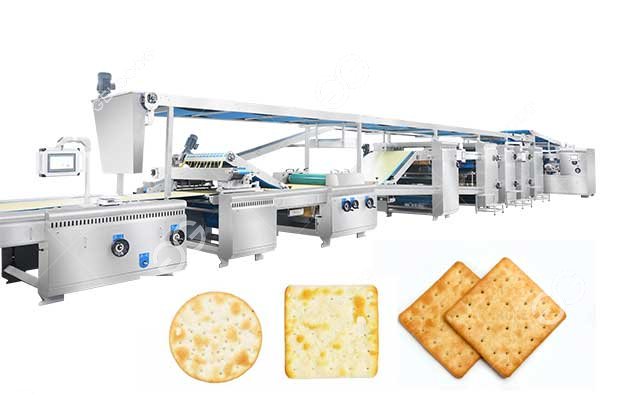

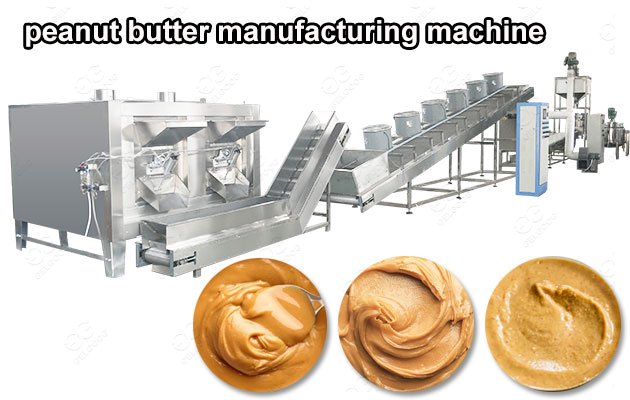

"Specific to the frying production line, only the stable operation of the equipment to do out of the product to ensure uniformity and stability." Industry, for example, if the front side of the hood machine speed and speed of the rear frying machine is not synchronized, the middle will Resulting in material loss or waste of time. Frying machine temperature instability will also affect product quality, resulting in waste.

From the point of the whole production line, every day will be in accordance with the design capacity to prepare the raw material for food production, such as the early stage of the need to unfreeze raw material, flavor, all kinds of accessories, then link problems once the production line equipment, raw materials may be frozen again or do other processing, a waste of resources, etc.

"From the original manual to easily, easy automatic promotion now, saves the manpower, the built-in pump oil circulating device delay the aging of the oil, and save energy." The industry said, from the point of the whole production line, change is huge, originally a line need 27 people, now a lot of link has been replaced with manipulator, only in flavor and the supplies mechanical link need manual operation, a line just three or four people.

He thinks, the domestic market in the increasingly mature, food processing not only requires high quality, automation, for safety, environmental protection and meet the requirements of the after-sales service are also rising.

"Specific to the frying production line, only the stable operation of the equipment to do out of the product to ensure uniformity and stability." Industry, for example, if the front side of the hood machine speed and speed of the rear frying machine is not synchronized, the middle will Resulting in material loss or waste of time. Frying machine temperature instability will also affect product quality, resulting in waste.

From the point of the whole production line, every day will be in accordance with the design capacity to prepare the raw material for food production, such as the early stage of the need to unfreeze raw material, flavor, all kinds of accessories, then link problems once the production line equipment, raw materials may be frozen again or do other processing, a waste of resources, etc.

"From the original manual to easily, easy automatic promotion now, saves the manpower, the built-in pump oil circulating device delay the aging of the oil, and save energy." The industry said, from the point of the whole production line, change is huge, originally a line need 27 people, now a lot of link has been replaced with manipulator, only in flavor and the supplies mechanical link need manual operation, a line just three or four people.

He thinks, the domestic market in the increasingly mature, food processing not only requires high quality, automation, for safety, environmental protection and meet the requirements of the after-sales service are also rising.

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Skype:jacobyaogelgoog

Skype:jacobyaogelgoog Русский язык

Русский язык