French Fries Making Machine|Finger Chips Production Line Quotation

Output:

Output: Voltage:

Voltage: Power:

Power:  Payment Method:

Payment Method:

Features

Finger Chips Production Line Introduction

The finger chips production line is to absorb the essence of the same products, retain the advantages of large-scale equipment enrichment, and reference to local users of the feedback information and design developed. The utility model has the advantages of low one-time investment, low energy consumption, many functions, small volume, high profit, convenient use and maintenance. The complete set of equipment consists of cleaning and peeling, cutting, blanching, dehydration, frying, oil removal, seasoning, packaging and other auxiliary equipment.

The finger chips production line is to absorb the essence of the same products, retain the advantages of large-scale equipment enrichment, and reference to local users of the feedback information and design developed. The utility model has the advantages of low one-time investment, low energy consumption, many functions, small volume, high profit, convenient use and maintenance. The complete set of equipment consists of cleaning and peeling, cutting, blanching, dehydration, frying, oil removal, seasoning, packaging and other auxiliary equipment.

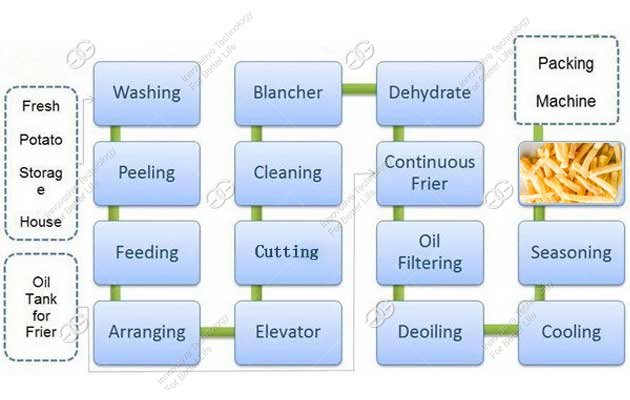

French Fries Making Machine Production Process

Lifting feed → cleaning peeling → selecting trim → lifting feed → cutting strip → rinsing → bleaching hot color → dehydration → frying → oil → seasoning → conveying → packing.

French Fries Production Line Main Equipment

1, Cleaning peeling machine: the use of gold steel sand liner cleaning peeling machine or brush-type cleaning peeling machine, can be completed at the same time cleaning, peeling work. High efficiency, low loss.

2, Slice cutting machine: can be sliced and cut strips. Slice thickness, cut bar size can be adjusted at will.

3, Bleaching hot machine: will cut good potato chips (strips) for rinsing, color protection.

4, Dewatering machine: centrifugal dehydration. Dehydration before frying can greatly shorten the frying time and improve the taste of potato chips. Improve production efficiency and reduce production cost.

4, Dewatering machine: centrifugal dehydration. Dehydration before frying can greatly shorten the frying time and improve the taste of potato chips. Improve production efficiency and reduce production cost.

5, Oil and water mixing frying machine: Because of the different proportion of oil, water, oil in the upper layer of heated fried potato chips, the residue directly deposited in the water, oil does not run black smoke, greatly prolong the use of the oil cycle, so that the cost of a substantial decline. The oil temperature control is accurate, thus ensuring the quality and taste of potato chips. After the work is finished, the water is released, and the residue will flow out along with the water.

6, Oil removal machine: centrifugal oil removal machine, will just fry good potato chips (strip) to remove oil, overcome the Potato Chips (section) High oil content, greasy mouth defects.

Improved the taste of potato chips (strips).

7, Automatic seasoning machine: drum-type seasoning machine using stainless steel production. The potato chips (strips) are evenly flipped in the rotation of the rollers, and are sprinkled or sprayed to add seasonings. It is not easy to break the seasoning evenly.

7, Automatic seasoning machine: drum-type seasoning machine using stainless steel production. The potato chips (strips) are evenly flipped in the rotation of the rollers, and are sprinkled or sprayed to add seasonings. It is not easy to break the seasoning evenly.

8, Nitrogen-filled packaging machine: packaging, in the packaging bag filled with nitrogen, can effectively prevent potato chips (strips) broken, extended shelf life.

GELGOOG Machinery Co., Ltd. is located in Zhengzhou, Henan province, adjacent to high-speed rail, traffic is very convenient. is a professional production of fried equipment, fruit and vegetable processing equipment, nut processing equipment, ice cream cone equipment, packaging equipment and other factories. Factory has independent import and export rights, independent inspection rights, with professional engineering and technical personnel and advanced mechanical processing equipment. To provide energy-saving, high efficiency, environmental protection, green science and technology products for the principle of customized processing for the user to meet the needs of the process production, reduce production costs, increase product value-added quality products.

GELGOOG Machinery Co., Ltd. is located in Zhengzhou, Henan province, adjacent to high-speed rail, traffic is very convenient. is a professional production of fried equipment, fruit and vegetable processing equipment, nut processing equipment, ice cream cone equipment, packaging equipment and other factories. Factory has independent import and export rights, independent inspection rights, with professional engineering and technical personnel and advanced mechanical processing equipment. To provide energy-saving, high efficiency, environmental protection, green science and technology products for the principle of customized processing for the user to meet the needs of the process production, reduce production costs, increase product value-added quality products.

Technical Data

| Item | Parameter |

| 1. Raw Potato Elevator |

0.75kw/380v/50HZ 2000*800*2000mm |

| 2. Potato Washing and Peeling Machine |

4.75kw/380v/50HZ 2600*900*1500mm |

| 3. Sorting Conveyor Line |

0.75kw/380v/50HZ 3000*900*900mm |

| 4. French Fries Cutter Machine |

1.5kw/380v/50HZ 950*800*950mm |

| 5. Rinsing Machine |

5.5kw/380v/50HZ 4000*1600*900mm |

| 6. French fries Blanching Machine |

125kw/380v/50HZ 4000*1600*950mm |

| 7. Air Dewatering Machine |

7.1kw/380v/50HZ 4000*1200*1400mm |

| 8. Sorting Conveyor Line |

0.75kw/380v/50HZ 3000*800*950mm |

| 9. Elevator |

0.75kw/380v/50HZ 2500*800*1300mm |

| 10. French Fries Frying Machine |

123kw/380v/50HZ 4500*1200*2600mm |

| 11. Vibrating Deoiling Machine |

1.5kw/380v/50HZ 1500*1000*1300mm |

| 12. Air Drying Machine |

7.1kw/380v/50HZ 4000*1200*1600mm |

| 13. Elevator |

0.75kw/380v/50HZ 2400*800*2200mm |

| 14. French Fries Flavoring Machine |

0.75kw/380v/50HZ 2600*1000*1600mm |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Skype:jacobyaogelgoog

Skype:jacobyaogelgoog Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online