Potato Starch Processing Line 1000kg/h

Output:

Output: Voltage:

Voltage: Power:

Power:  Payment Method:

Payment Method:

Features

Introduction :

Potato starch production line is also suitable for Yam/Cassava/Sweet Potato starch processing.

Potato Starch Making Process is Cleaning and Peeling--Grinding--Dewatering--Drying--Screening—Packaging. In the crushing section, our Curved Mesh Crusher with national patent is used in grinding and screening setions, it smash the material after multi-level filtering, multi-stage extrusion by a unique processing cycle, with low energy consumption, high starch extraction rate and good quality.

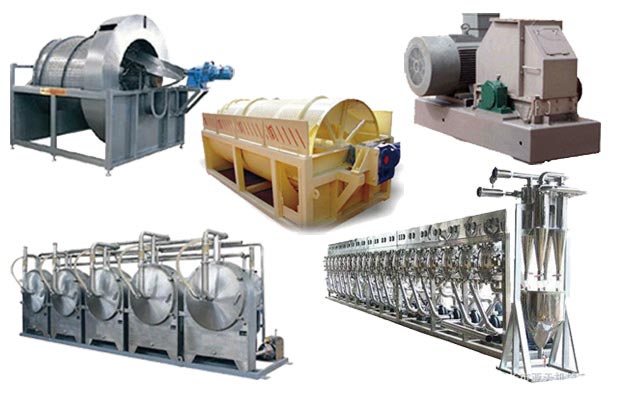

The whole production line machines includes: Feeding Machine; Washing Machine; Grinder; Starch extraction Machine; Desander; Starch refine system; Drying Machine; Packaging Machine for Flour.

Potato starch production line is also suitable for Yam/Cassava/Sweet Potato starch processing.

Potato Starch Making Process is Cleaning and Peeling--Grinding--Dewatering--Drying--Screening—Packaging. In the crushing section, our Curved Mesh Crusher with national patent is used in grinding and screening setions, it smash the material after multi-level filtering, multi-stage extrusion by a unique processing cycle, with low energy consumption, high starch extraction rate and good quality.

The whole production line machines includes: Feeding Machine; Washing Machine; Grinder; Starch extraction Machine; Desander; Starch refine system; Drying Machine; Packaging Machine for Flour.

Plant:

this project covers an area of about 400 square equipment, the plant generally is not small than 1,000-square

Power:

380 volts, 3 phases, 50 Hertz, the largest floating voltage 6% and 4% of the maximum frequency of floating.

The installed capacity:

About 180KW, the actual consumption: about 150KW

Water:

The extraction Section 15-20 cubic / hour, at room temperature, in line with the drinking water standard.Section 10 cubic cleansing / hour, can be part of the cycle, can also be used latter water Dryer, 1-2 tons of user-owned boiler, hot stove can also be used in our plant.

Technical Data

|

ITEM |

Name and model | Unit |

Quantit Y |

Power |

REMARK |

| First |

Clean machine |

||||

| 1 |

Water power convey groove |

||||

| 2 |

Cleaning machine Ⅰ |

set | 1 | 3 |

Carbon steel |

| 3 |

Cleaning machine Ⅱ |

Set | 1 | 1.5 |

Carbon steel |

| 4 |

Potato cleaning convey machine |

set | 1 | 3 |

Carbon steel |

| Second |

Extraction and refining section |

||||

| 1 |

extrusion-milling machine (making powder ) |

Set | 1 | 30 |

Carbon steel |

| 2 |

Fine filter (latex) |

Set | 2 | 3 |

Carbon steel |

| 3 |

Starch micro-filtration machine |

Set | 1 | 1 | |

| 4 |

Desanding machine |

Set | 1 | 3 |

Carbon steel |

| 5 |

Refined starch concentration system |

Group | 11 | 66.5 |

Carbon steel |

| 6 |

Automatic vacuum dryer |

set | 1 | 14 | |

| 7 |

Conveyor |

set | 1 | 3 |

According to the distance charge |

| 8 |

Interim tank |

||||

| Third | Dry section | ||||

| 1 | Air dryer | Set | 1 | 28 |

Aluminum alloy |

| 2 | Radiator | Set | 1 |

Carbon steel |

|

| 3 | Starch screen | Set | 1 |

Carbon steel |

|

| 4 | Distribution Cabinet | Set | 1 | ||

| 5 | A ton of boiler | Set | 1 | ||

| Fourth | Aid machine | ||||

| 1 | Power line | ||||

| 2 | Packing machine | 1 | |||

| 3 | Pipelined and pump/motor | 3 | |||

| 4 | Non-standard parts and other materials | 2 | |||

| 5 |

Distribution Cabinet |

Set | 3 | ||

| 6 | To guide the design and debug |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Skype:jacobyaogelgoog

Skype:jacobyaogelgoog Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online