Hot sale Wafer biscuit Production Line

Output:

Output: Voltage:

Voltage: Power:

Power:  Payment Method:

Payment Method:

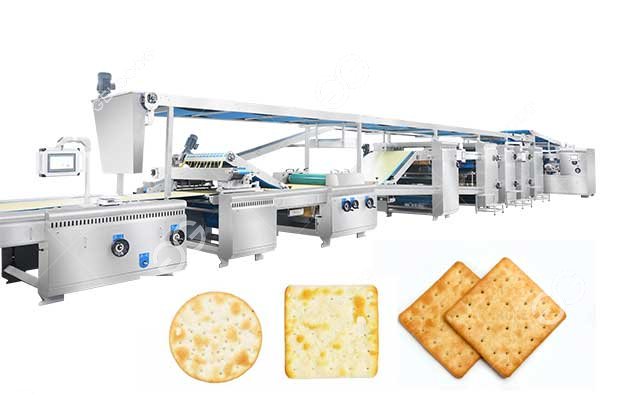

GELGOOG Series Wafer Biscuit Production Line is the primary choice for the production of kinds of hard and soft wafer biscuit.

The biscuit plant equipment can be combined and displayed according to customer’s local space or biscuit technical requirement.

Adopting hearing-medium conduction technology with heating oil as medium, the plant is a new generation product developed exclusively in China based on the advanced structure of existing plants from domestic market and abroad.

If offers an ideal solution for lower power consumption and overall production cost, and keeping the same surface color for all biscuits.

Advantages of wafer biscuit machine:

1.Reliable performance, stable operation, long service life.

2.By changing the molds and recipes, this plant is able to produce various types of high quality biscuit, such as cream biscuit, sandwiching biscuit, soda cracker biscuit, animal biscuit, vegetable biscuit etc.

3.There are diversified heating source for your operation (Electric, gas, fuel oil).

4.High automatic, stand-alone machine can be controlled separately, simple operation and easy maintenance

5.We have approved by CE、ISO and SGS. They all are proves of our high quality.

6.The plant is a new generation product developed exclusively in China based on the advanced structure of existing plants from domestic market and abroad.

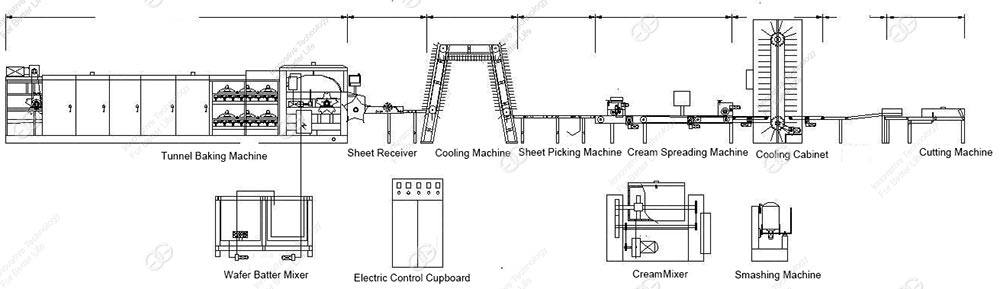

| No. | Equipment Name |

Dimension(mm) (L*W*H) |

Power | Qty |

| 1 | Batter Mixer (GGJ) | 1720*1100*1000 | 4.5Kw | 1 |

| 2 | Gas Baking Oven (GGHG-27) | 10550*1700*2260 | 5.52Kw | 1 |

| 3 | Wafer sheet connecting machine (GGJP-5) | 2300*700*850 | 0.37Kw | 1 |

| 4 | Door Type Wafer Sheet Cooling Machine | 3280*700*2700 | 0.37Kw | 1 |

| 5 | Sheet Collecting Machine (GGP4) | 2000*700*760 | 0.18Kw | 1 |

| 6 | Cream spreading machine (GGC4) | 3000*1160*1300 |

380V.2.24Kw 220V.2Kw |

1 |

| 7 | Vertical cooling tower (GGLF) | 3130*1200*3660 | 1.11Kw | 1 |

| 7-1 | Cold Blower | 2200*1100*1800 | 8.86Kw | 1 |

| 8 | Wafer Cutting Conveyor (GQS) | 1500*700*780/1100 | 0.18Kw | 1 |

| 9 | Blade Type Cutting Machine (GGJDX4) | 1620*2300*1240 | 0.75Kw | 1 |

| 10 | Horizontal type cream mixer (GGWG) | 1840*850*1350 | 5.05Kw | 1 |

| 11 | Smashing machine (GGF) | 670*660*1000 | 3Kw | 1 |

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Skype:jacobyaogelgoog

Skype:jacobyaogelgoog Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online