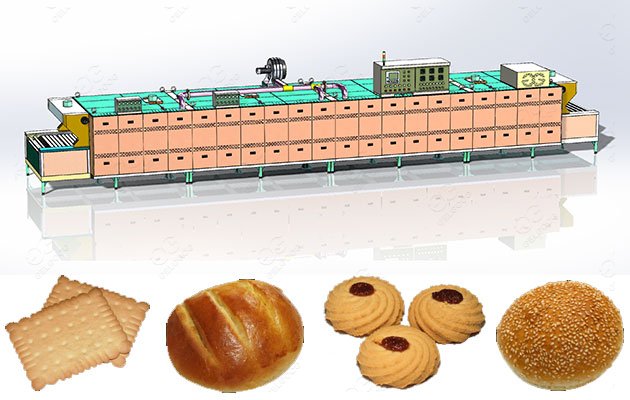

With many years of production experience, the company specializes in providing various pastry processing solutions: fried chicken nuggets solution, biscuit solution, spring roll solution, cake solution, etc.

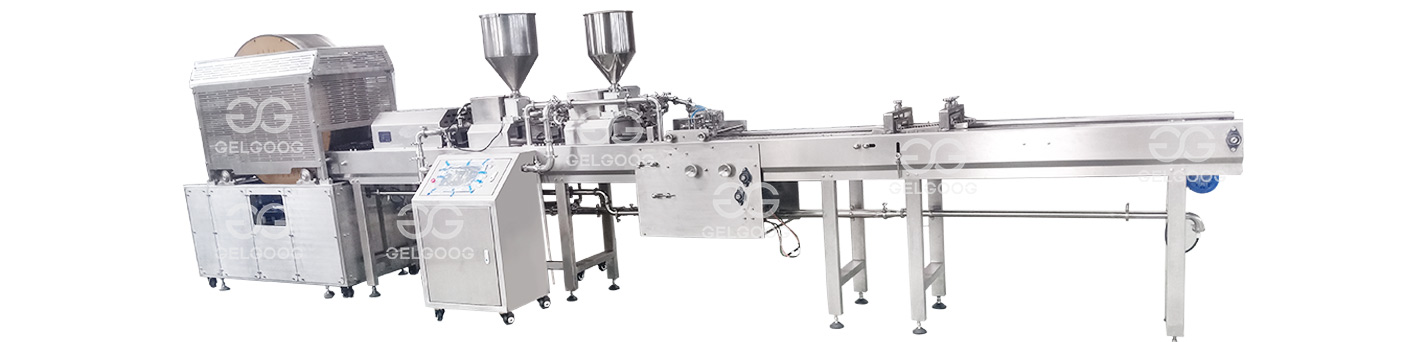

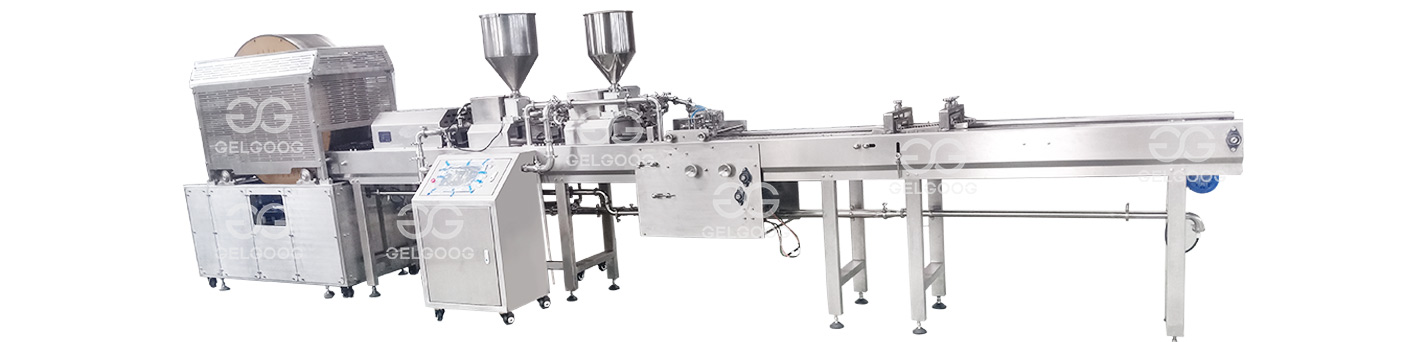

The full spring roll production line can make spring rolls automatically, and it can produce 1500-3500 pieces per hour. Just pour the mixed batter and fillings into the storage tank, and the batter is baked to form a spring wrapper. Then go through the steps of cooling, cutting, filling and rolling, etc, this production line can produce spring rolls of uniform size and good taste.

Features of Automatic Spring Roll Production Line

1 The frame of the whole set of equipment is made of 304 grade stainless steel, which can not only ensure safe production, but also prevent corrosion.

2 The baking wheel, roller, drive shaft, etc. are made of carbon steel and polyurethane.

3 The conveying mesh belt is a 1.5mm herringbone mesh belt, and the inside and outside of the conveying pump are made of 304 material.

4 The mixer and slurry tank are made of 2.0mm thick stainless steel plates.

5All panels of the whole set of equipment have a decorative thickness of 1.2mm and a reinforcement of 5mm-8mm.

6The weight range of spring rolls: 15-150 grams.

What Can We Do ?

Customize Your Product Needs for You

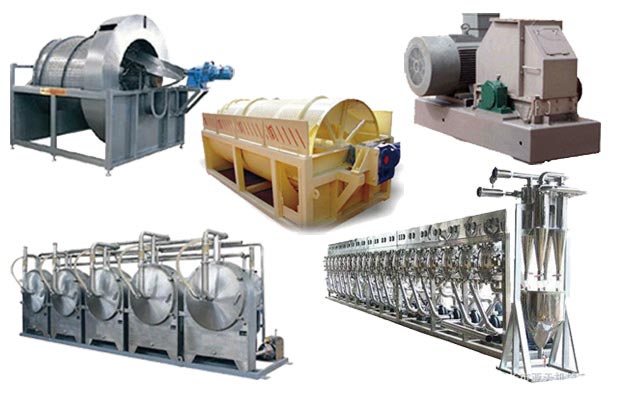

Single Machine in the Production Line

Please fill in the form below to get a free quote. We will get back to you within 12 hours.

Русский язык

Русский язык