Commercial Rice Noodle Making Machine for Pad Thai Production

Output:

Output: Voltage:

Voltage: Power:

Power:  Payment Method:

Payment Method:

Features

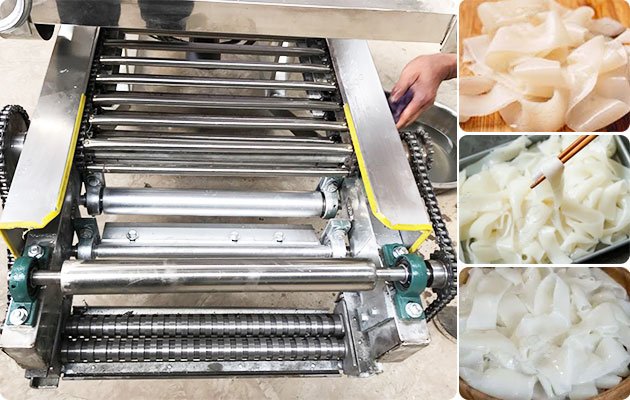

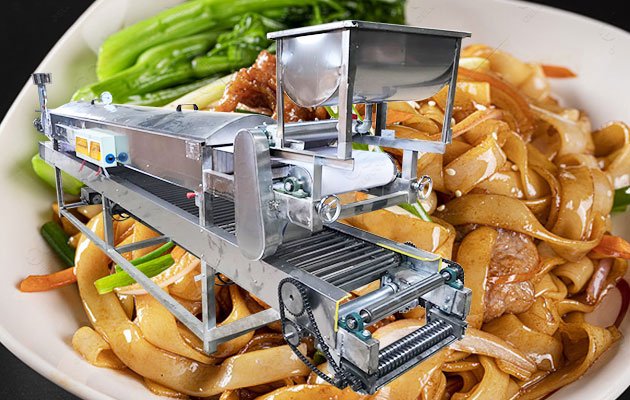

Commercial Rice Noodle Making Machine is used for making and steaming the rice noodles. Automatic operation, it can finish the adding oil, molding, steaming, cutting within one machine, it is an ideal machine for pad thai production.

The whole machine mainly includes the following parts: rice milk bucket, steam box, thermometer, oil hopper, conveyor belt, cooling fan and so on. Automated operation, high work efficiency, saving manpower and cost. The rice noodles produced by this machine completely preserve the nutrients of the rice. The rice noodles are of good quality, that is, they are nutritious and hygienic.

Working Principle of Commercial Rice Noodle Making Machine

◆ The machine mainly used for filling the grind rice milk into the machine, and though the machine for steaming, cutting, and then cooling into cold rice noodle.

◆ The raw material is rice, rice after washing and grinding into powder, add water into the powder to make rice paste,steamed into rice noodle. The original rice noodle is white,but you can add the vegetable juice or fruit juice to made colorful and nutrient-rich rice noodle.

Advantages of Pad Thai Making Machine

1. Made of stainless steel, this commercial rice noodle making machine with good appearance, clean and beautiful, strong and durable.

2. Using direct thermal heating, heating fast, low fuel consumption than ordinary rice noodle machine saving more than 40%.

3. Fully automatic operation, with automatic pulping, steaming, slitting, cooling and powder collection functions.

4. Wide adaptability, liquefied gas, electric heating, natural gas, etc. can be used as heating fuels, with a wide range of options.

5. Production speed, thickness and temperature control, etc., can be adjusted according to customers' demand.

Characteristics of Commercial Rice Noodle Machine

1. Complete preservation of the nutritional content of rice, ho fun noodles good quality, not only nutritious, but also the health and delicious.

2. Spindle use special steel, and the strict heat treatment, make its significantly longer service life.

3. The machine with spindle bold, extended, and motor power, and to greatly improve the yield.

4. Dashboard and the workbench is installed in the same position, all parameters marked intuitive and convenient operation.

Working Video of Automatic Pad Thai Machine

Working Video of Automatic Pad Thai Machine

Technical Data

| Model | GG-50 | GG-60 | GG-80 | GG-120 | GG-150 | GG-250 | GG-350 | GG-500 |

| Capacity(KG/H) | 50 | 60 | 80 | 120 | 150 | 250 | 350 | 500 |

| Power(KW) | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 | 0.75 | 0.75 |

| Voltage(V) | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 |

| Dimension(M) | 2.6*0.6*1.2 | 2.9*0.6*1.2 | 3.7*0.7*1.2 | 4.1*0.7*1.2 | 4.1*0.9*1.2 | 5.7*0.9*1.2 | 5.8*1.1*1.2 | 8.5*1.1*1.3 |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online