Frozen Spring Roll Production Line 3000-4000PCS/H

Output:3000-4000PCS/H

Output:3000-4000PCS/H Voltage:380 V

Voltage:380 V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

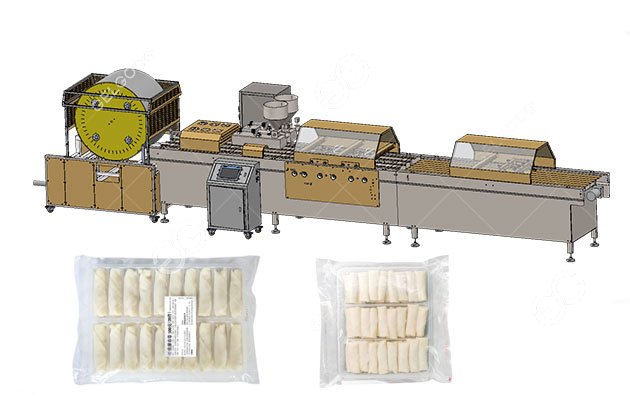

The automatic frozen spring roll production line is specially used to produce large capacity spring rolls and then freeze spring rolls in a short time.

We have developed different models of production lines according to your needs, including 1000-3000pcs/h, 3000-4000pcs/h and 5000-7000pcs/h. The whole line has a high degree of automation and high work efficiency.

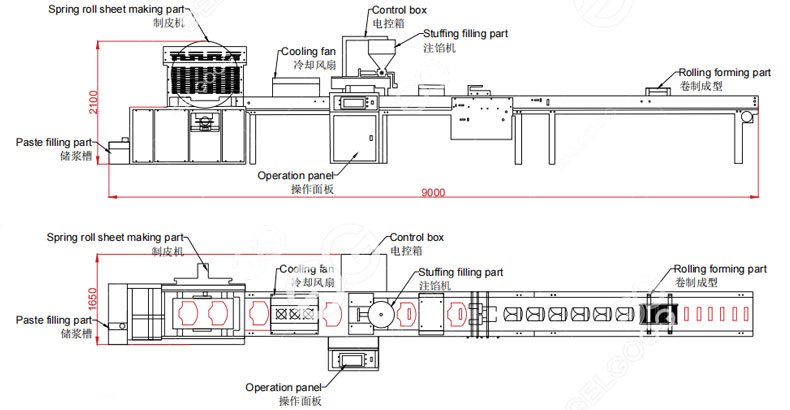

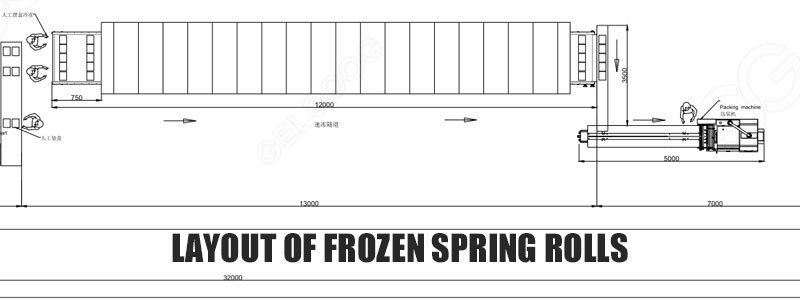

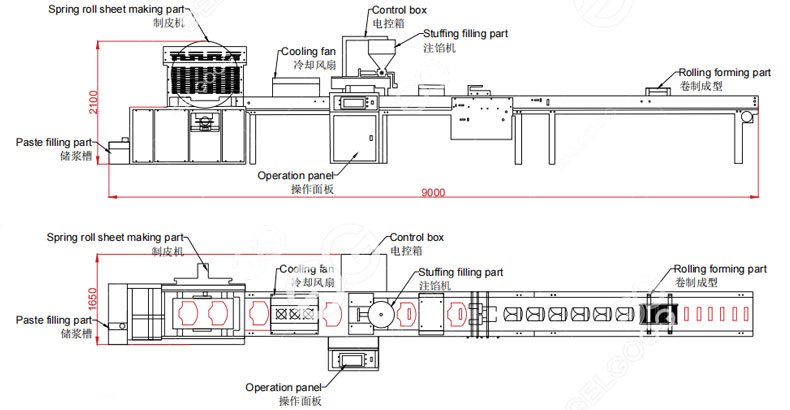

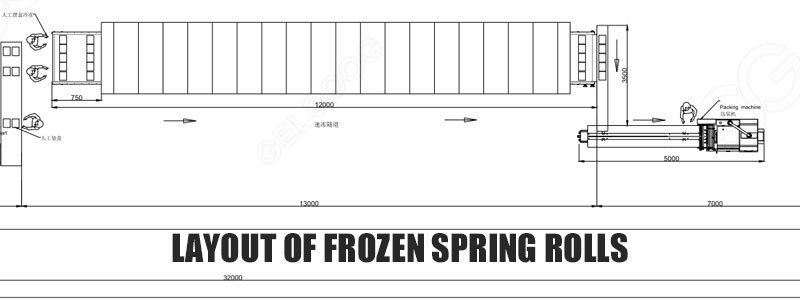

Composition of the Production Line

The whole spring roll processing line is mainly composed of baking machine, cutting machine, cooling machine, conveyor belt, filling machine, folding machine, rolling machine, quick freezing machine, packaging machine and so on. Continuous work, high production capacity, to meet the needs of large food processing plants.

Variety of Flavors:

The automatic frozen spring roll production line can easily make spring rolls of various popular flavors, such as spring rolls with vegetarian fillings such as shiitake mushrooms, shredded carrots, cheese, red bean paste, and chopped vegetables, as well as seafood spring rolls with minced meat and shrimp, and spring rolls with meat stuffing.

Features of Industrial Frozen Spring Roll Production Line

- Batter Mixer: The machine is used to mix various ingredients together and mix these ingredients evenly by stirring to form a smooth batter.

- Batter Baking Machine: The grout pump lifts the batter near the baking pan, and through the nozzle, the batter sticks to the baking wheel. The batter is baked in a thin sheet.

- Filling Dispenser: The filling dispenser is designed to accurately portion and dispense the desired amount of filling onto the dough sheets. It ensures consistent filling distribution and avoids over or under filling.

- Rolling Machine: This machine automates the process of rolling the filled dough sheets into cylindrical shapes, creating the characteristic spring roll shape. It maintains a tight and secure roll to prevent filling leakage during freezing.

- Freezer: The freezer is a crucial component that rapidly freezes the spring rolls to preserve their freshness and extend their shelf life. It utilizes quick freezing technology to maintain the quality and texture of the spring rolls.

- Packaging Machine: Once the spring rolls are frozen, they are transferred to the packaging machine. This machine efficiently wraps the individual spring rolls in a protective packaging material, ensuring hygienic storage and easy handling for consumers.

Frozen Spring Roll Line Working Video

Technical Data

| GG-CJX5000 Spring Roll Production Line | |||

| Name | Dimensiton(mm) | Power(KW) | No. |

| Spring Roll Wapper Part | 2200*2000*2200 | 59 | 1 |

| Stuffing Part | 700*600*1000 | 0.4 | 1 |

| Spring Roll Folding Part | 1700*500*1360 | 0.4 | 1 |

| Spring Roll Forming Part | 4030*500*1100 | 0.4 | 1 |

| Batter Mixer | 1300*600*900 | 1.1 | 1 |

| Batter Tank | 800*300*320 | / | 1 |

| Batter Pump | - | 0.55 | 2 |

| Capacity 3000-4000pcs/h | |||

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online