Automatic Cream Crackers Production Line Supplier

Output:500KG/H

Output:500KG/H Voltage:380V 50HZ 3PH

Voltage:380V 50HZ 3PH Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

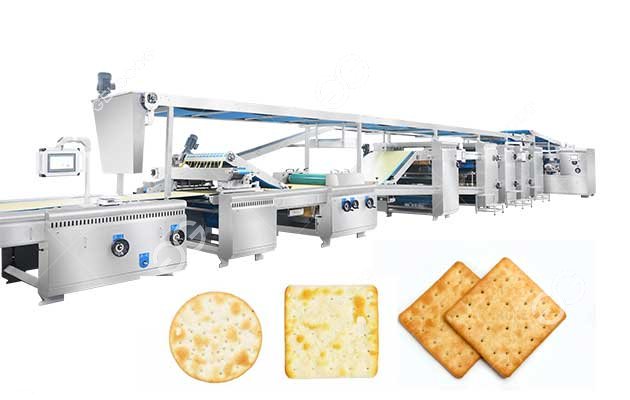

The automatic cream crackers production line is an efficient and automated solution specially designed for cream crackers. The company can provide quality equipment and services for your biscuits business.

The main components of the production line include dough mixers, laminating machines, dough pressing machines, forming machines, ovens, oil spraying machines, cooling machines, packaging machines, etc.

Cream Cracker Line Functions

- Mixing and Stirring: Advanced mixing equipment can ensure that the ingredients are fully mixed to make the creamy wafers more uniform.

- Forming and Cutting: The production line is capable of automatic forming and cutting, ensuring the buttery wafers are of consistent shape and size.

- Baking and cooling: Equipped with efficient baking system and cooling machine to ensure the crispness and taste of cream biscuits.

- Packaging and encapsulation: The final stage includes automatic packaging and encapsulation, which improves production efficiency and ensures the hygiene and quality of the product.

Automatic Cream Crackers Production Line Features

- Fully Automated Production Process: It realizes a fully automated production process from raw material preparation to packaged finished products, reducing manual intervention and improving overall production efficiency.

- Flexible and Adjustable Production Capacity: The equipment supports flexible adjustments to meet various scales and types of cream cracker production requirements.

- Advanced Intelligent Control System: Equipped with an intelligent control system, ensuring production stability, controllability, and reducing operational complexity, ultimately enhancing product quality.

- Energy-Efficient and Environmentally Friendly Design: The cream crackers line incorporates energy-efficient technologies, minimizing energy consumption and aligning with contemporary environmental standards.

- Easy Maintenance and Upkeep: With a simple structure, the line is easy to maintain and upkeep, minimizing downtime due to equipment failures and ensuring the stability of the processing line.

Cream Crackers Processing Line Supplier

Gelgoog is a leading enterprise specializing in the manufacturing of biscuit food production machine. We have advanced production lines and technical teams, and our products sell well in many countries. For example, Bangladesh, Iraq, Indonesia, Malaysia, Ethiopia, Kenya, Iran, Vietnam, etc.

With quality as our core, we continue to innovate and are committed to providing excellent customized solutions to global biscuit manufacturers. Our automatic cream crackers production line has been successfully exported to many countries and has been highly praised by customers. When you choose Gelgoog Company, you will get high quality machine and professional support to help you succeed in the biscuit market.

Cream Crackers Production Process

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online