Breakfast Puffed Grain Machine|Corn Flakes Production Line

Output:

Output: Voltage:

Voltage: Power:

Power:  Payment Method:

Payment Method:

Features

Description of Automatic Corn Flakes Production Line

Corn flakes is one of the puffed grain, is a new type of breakfast food with high nutritional value. It is mainly made of cereals and processed by cooking or extrusion. The puffed grain machine is widely used for puffed wheat, rice manufacturing.

The Characteristics of Corn Flakes Production Line

Corn flakes is one of the puffed grain, is a new type of breakfast food with high nutritional value. It is mainly made of cereals and processed by cooking or extrusion. The puffed grain machine is widely used for puffed wheat, rice manufacturing.

The Characteristics of Corn Flakes Production Line

1) Ingredients: The ingredients of corn flakes are very important. The seasoning must ensure a good taste, especially the requirements of corn raw materials, which is directly related to the ability to make high-quality corn flakes products, and the ratio of various nutrients, content.

2) Extrusion ripening: The process of extruding and curing of corn flakes is the key to producing high-quality corn flakes. Corn flakes must be fully cooked without any puffing. Only in this way can corn flakes be made dense, hard and crisp with outstanding flavor.

3) Cutting: Cut and ripe the single-screw extruder into granulated materials of the same size. The materials are translucent.

4) Pre-drying: The cut and formed materials enter the dryer for pre-drying. After the surface is dried, a certain tension is formed, which no longer adheres to each other, which is conducive to the smooth progress of tabletting.

5) Tableting: The tableting process is also the key in the production of corn flakes. The requirements for the tableting machine are very high. The surface of the roll must have a high degree of smoothness, and the roll must be constant temperature.

6) High-temperature roasting: Whether the corn flakes product has a hard, crisp, dense structure and outstanding corn flavor, the roasting process is very important.

7) The baked corn flakes are corn flakes products after cooling. At present, there are also many corn flakes for post-processing, sugar-coated, salt-fried or chocolate-coated, mostly based on market demand.

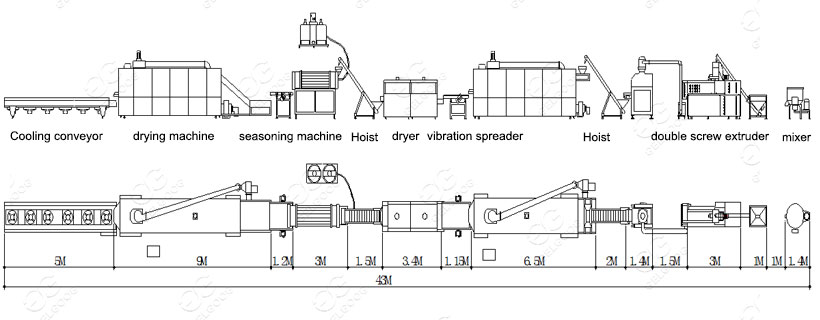

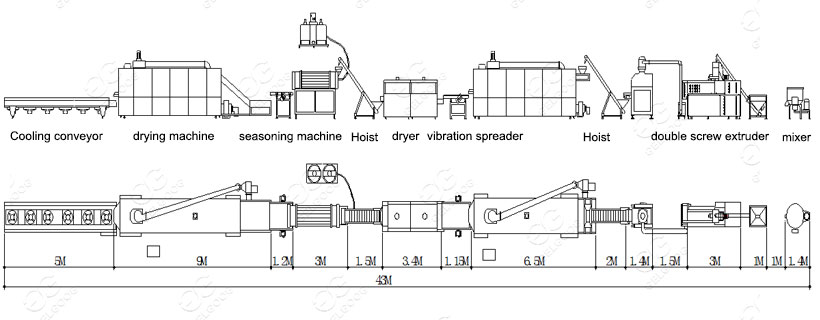

Equipment Composition of Puffed Corn Flakes Making Machine

Mixing machine → Feeder → Screw extractor → Traction cutting machine → Z-type conveyor → Five-layer drying box → Z-type conveyor → Continuous fryer → Deoiling machine → Seasoning machine

The Advantages of Breakfast Puffed Grain Machine

The Advantages of Breakfast Puffed Grain Machine

1. The production line has been continuously improved, with a higher degree of automation, high efficiency and large output.

2. The raw materials have been changed from corn kernels at the beginning to corn flour, and single screw extruder instead of cooking.

3. Extrusion is also completed on the extruder at one time. By pre-drying and tableting, the product is more uniform and tastes better.

4. Use the drying oven to bake puffed grain to make the product's flavor more prominent.

5. Corn flakes production line has different output options to meet the needs of different customers.

5. Corn flakes production line has different output options to meet the needs of different customers.

Technical Data

| Name | Model | Capacity | Power | Size |

| Mixing machine | GGBF-III | 50kg/time | 5.5kw | 1350*1050*1200 mm |

| Screw Mixer | GGZLSJ | 110-140kg/h | 1.12kw | 3000*850*2400mm |

| Single screw host | GGDLG130 | 110-140kg/h | 43kw | 4100*1100*2260mm |

| Cutting Machine | GG130FQ | 110-140kg/h | 1.75kw | 3600*1060*1400mm |

| z-type conveyor | GGFLS | 110-140kg/h | 0.55kw | 4000*900*1200mm |

| Five-layer drying oven | GGWHX-II | 200-250kg/h | 10.2kw | 12000*1400*3000mm |

| z-type conveyor | GGFLS | 110-140kg/h | 0.55kw | 4000*900*1200mm |

| Frying Machine | GGLXZ4000 | 800-15000kg/h | 4200*1350*2300mm | |

| Deoiling Machine | GGSYX | 110-140kg/h | 2.2kw | |

| Seasoning line | GGPG-PF-LQ | 100-200kg/h | 3.86kw | 4800*800*1850mm |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online