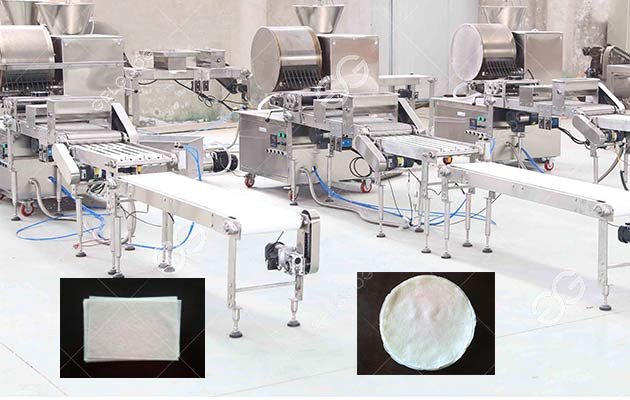

Spring Roll Wrapper Maker Machine Electric Gas Heating

Output:1000-1500pcs/h

Output:1000-1500pcs/h Voltage:380V

Voltage:380V Power: 18kw

Power: 18kw Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

Working Principle of Spring Roll Wrapper Maker Machine

In accordance with the production process of the slurry, the surface slurry is made well. After heating the flour through a round roast wheel, it becomes a fixed thickness of spring roll wrappers or other flaky food. The most important thing is to adjust the batter of different recipes to make other products, such as crepes, pancakes, lumpia wrappers and so on.

Spring Roll Wrappers Technological Process

The slurry prepared into slurry tank, according to the technological requirements when heated to a suitable temperature bake round after the start will be sent to the surface of the slurry pump nozzle, operation clutch lever, the surface plasma arc surface adhesion in baking process round, with the baked wheel 270-300 degrees. When the surface curing slurry automatic, and roasted round of separation, to form a fixed thickness of the skin or immediately roll Spring rolls spring rolls. The heating mode of the roast wheel is divided into electric heating and gas heating for the user to choose.

Features of Spring Roll Wrapper Maker Machine

1.Enhanced Counting and Surface Pressure Mechanism

This feature integrates an automated counting system for precise tracking of production quantities. The continuous pressure surface conversion mechanism ensures consistent quality and texture in each product.

2.Advanced Photoelectric Counting with Integrated Dust Management

Utilizing photoelectric sensors, this function provides accurate counting of items. The inclusion of an automatic dusting feature helps in maintaining the cleanliness of the products, reducing manual cleaning efforts.

3.Precision Thickness Adjustment via Eccentric Wheel

The thickness of the output can be finely tuned using an eccentric wheel, allowing for a high degree of customization in product size and consistency, catering to diverse production needs.

4.Programmable Automatic Shutdown Feature

This function allows operators to set specific times for the machine to automatically power down, enhancing operational efficiency and safety, while also conserving energy.

Dual-Layered Safety Mechanism

The machine is equipped with a double-layered safety system, designed to safeguard operators and ensure a risk-free working environment. This feature is crucial in preventing accidents and ensuring uninterrupted operation.

Spring roll skin machine after-sale service:

(1) our company has a one-year free warranty on the products sold and the commitment to life-long maintenance.

(2) The company is responsible for the installation and commissioning of the equipment on the site. Ensure that the equipment is a brand new product according to customer needs.

(3) To provide specific training for the technicians of the demand side, so as to facilitate the normal operation and operation of the equipment.

(4) The equipment factory is equipped with instructions, company publicity materials, maintenance card and certificate of qualification.

Video of Spring Roll Wrapper Machine

Technical Data

| Model | GGSR-5029Y/F | GGSR-8045Y/F | GGSR-12060Y/F |

| Voltage | 380/220V(50/60HZ) | 380/220V(50/60HZ) | 380/220V(50/60HZ) |

| Power | 18kw | 40kw | 59kw |

| Host power | 0.4kw | 0.4kw | 0.75kw |

| Cutter power | 0.2kw | 0.2kw | 0.2kw |

| Conveyor belt power | 0.36kw | 0.36kw | 0.55kw |

| Capacity | 1000-1500pcs/h | 3500-4500pcs/h | 4500-7000pcs/h |

| Size | 5200*950*1350mm | 6200*1100*1600mm | 6200*1300*2000mm |

| Net Weight | 520kg | 1000kg | 1750kg |

| Thickness of Dosa | 0.3-2.0mm | 0.3-2.0mm | 0.3-2.0mm |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online