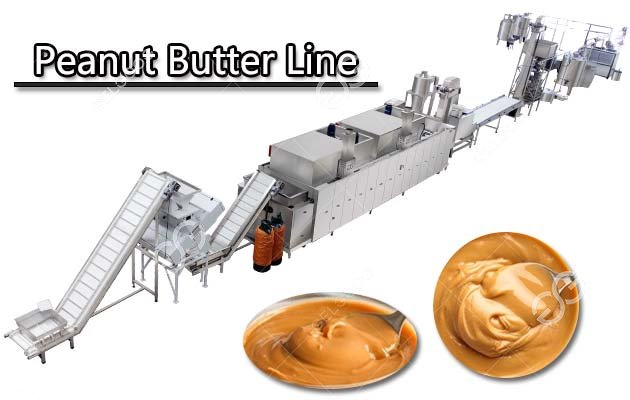

Complete Automatic Peanut Butter Production Line 0.5-1T/H

Output:0.5-1 T/H

Output:0.5-1 T/H Voltage:380 V

Voltage:380 V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

An automatic peanut butter production line is an industrial equipment designed to efficiently and consistently manufacture peanut butter on a large scale. The popular output is 0.5-1t.

The complete production line includes peanut roaster, peanut peeling machine, peanut butter grinder, flavoring machine, mixing tank, homogenizer, fine peanut butter grinding machine, vacuum tank, cooler, filling machine etc.

Application of Peanut Butter Production Line

This peanut butter line can be used not only for processing peanut butter(groundnut butter), but also for processing tahini(sesame paste), almond butter, walnut butter, hazelnuts butter, melon seeds butter and other nut butters. It is the first choice equipment for many butter processing plants.

There is a conveyor belt or a hoist connection between each machine, and the work is continuous and efficient. On average, this peanut butter processing line can make 100-1000 kg of peanut butter in one hour, also can be customized by your demand.

There is a conveyor belt or a hoist connection between each machine, and the work is continuous and efficient. On average, this peanut butter processing line can make 100-1000 kg of peanut butter in one hour, also can be customized by your demand.

Features of Peanut Butter Line

- Use the advancements in food processing technology, enabling the mass production of high-quality peanut butter while ensuring product safety and consistency.

- The industrial peanut butter production plant uses high-quality components, which has the superior performance and durable equipment.

- This line has the high degree of automatic, easy operating, integrated control, the operation process is relatively stable.

- The peanut butter line is made of stainless steel 304, the peanut butter produced not only tastes good, but is also relatively safe.

- The output is diversified, the hot sale capacity is 500-1000 kg per hour, you can also choose according to your own needs.

- Full enclosed production, no pollution, the finished peanut butter meet the export standard. Main export countries are Zambia, UK, Italy, India and many other countries.

Key Process of the Nut Butter Production Line:

- Grinding: Put the peeled peanuts into the peanut grinder, which can grind peanuts into peanut butter. If you want a more delicate taste, we also have an ultra-micro grinder that can grind peanuts into peanut butter with a smooth taste.

- Mixing and Flavoring: In some cases, additional ingredients like salt, sugar, or stabilizers may be added at this stage to enhance flavor and texture. These ingredients are carefully mixed into the peanut paste.

- Homogenization: The peanut paste is passed through a homogenizer, which further refines the texture and consistency of the peanut butter. This step helps prevent oil separation and ensures a smooth, uniform product.

- Packaging: The final peanut butter is then pumped into containers, jars, or other packaging formats. Automatic filling and sealing machines ensure precise quantities and a secure seal to maintain product freshness.

Video of Groundnut Butter Production Line

In summary, an automatic peanut butter production line is a highly efficient and precise equipment that transforms raw peanuts into high-quality peanut butter products.

Its automation capabilities, quality control measures, and flexibility in production make it a valuable asset for food processing companies seeking to meet the demand for this beloved spread while ensuring consistency and safety in their products.

Technical Data

| No. | Item |

Power (kw) |

Dimension (mm) |

| 1 | Roaster Machine | 118 | 4700*2900*1650 |

| 2 | Conveyor | 0.75 | 5000*500*900 |

| 3 | Cooling Conveyor | 8.1 | 10000*1200*1600 |

| 4 | Peeling Machine | 1.5 | 1000*1000*1400 |

| 5 | Kernel and Skin Separating Machine | 3 | 1800*1000*1500 |

| 6 | Sorting Conveyor | 0.75 | 6000*700*1000 |

| 7 | Elevator | 0.75 | 1000*500*3400 |

| 8 | Storage and Feeding Hopper Machine | 0.55 | 1100*1100*2400 |

| 9 | Grinding Machine | 11x4 | 900*350*900 |

| 10 | Flat Table | 2300*2000*600 | |

| 11 | Storing Tank | 500L | |

| 12 | Paste Pump | 1.5 | 1000*300*350 |

| 13 | Mixing Tank | 4 | 800L |

| 14 | Vacuum Degassing Tank | 6.2 | 800L |

| 15 | Paste Pump | 2.2 | 1100*350*350 |

| 16 | Storing Tank | 3 | 800L |

| 17 | Electric Control Cabinet |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online