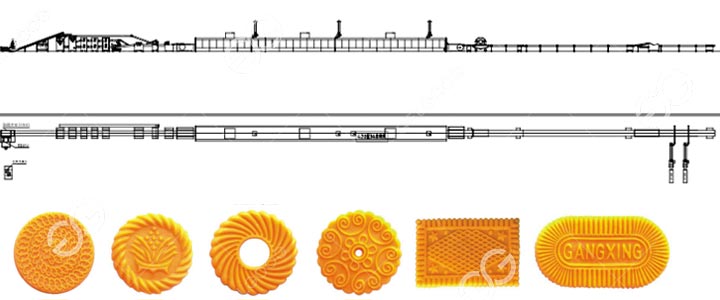

Complete Biscuit Production Line Multiple Purposes

Output:300-1200KG/H

Output:300-1200KG/H Voltage:380V,50HZ,3PH

Voltage:380V,50HZ,3PH Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

Complete biscuit production line manufacturers use this professional equipment for high-volume biscuit production. The biscuits are not only of high quality but also come in a wide variety to meet the growing demand for biscuits.

Whether it is soda crackers, vegetables crackers, or sandwich biscuits, bear biscuits, advanced equipment can be used to achieve efficient production. The biscuit industry has achieved significant development over the years.

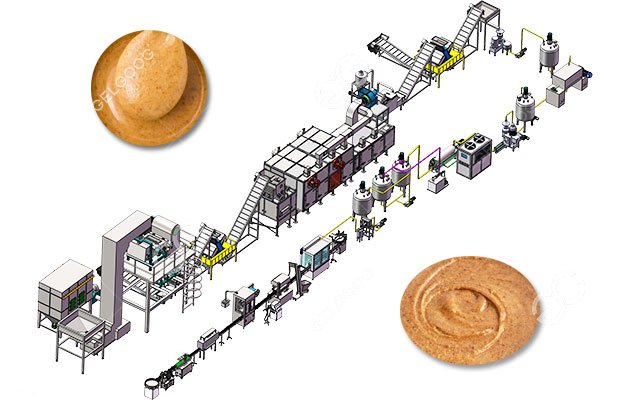

The key parts and characteristics of the automatic biscuit production line are shown below.

Industrial biscuit production lines have revolutionized the biscuit manufacturing industry by increasing efficiency, consistency, and production capacity. These state-of-the-art systems have allowed for a wider range of biscuit varieties to meet the diverse tastes of consumers worldwide. As technology continues to advance, we can expect even more innovation in biscuit production, catering to evolving consumer preferences while maintaining the deliciousness and quality we associate with biscuits.

The key parts and characteristics of the automatic biscuit production line are shown below.

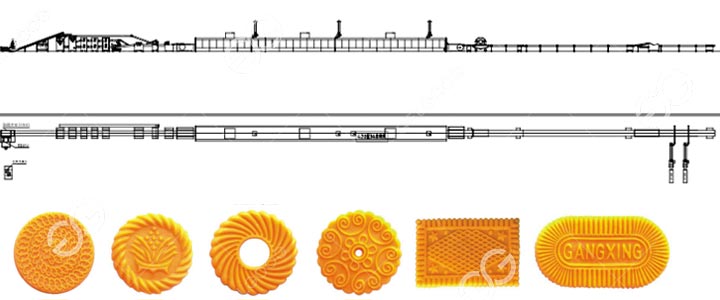

●Mix Ingredients to Make Dough: Prepare flour, sugar, oil, condiments, etc. according to the biscuit recipe and mix them in precise proportions. Mixer machine can mix both hard biscuit dough and soft biscuit dough. The hard biscuit dough has a smooth surface, while the soft biscuit dough is crumbly and not lumpy.

●Press the Dough into Sheet: After the dough is mixed, it is sent to the pressing stage via an elevator. There are multiple processes to roll the dough into thin sheets. The thickness of the dough strip is usually 0.6-0.8 mm.

●Biscuit Baking: Baking is a key stage in biscuit production. During this process, it will go through the rising, setting, dehydration, and coloring stages, and finally become the food we know and love. Precise time and temperature settings during baking are crucial to getting the texture and flavor your biscuits want.

●Biscuit Spraying: In order to make the biscuits shiny and brightly colored, they can be sprayed with oil after baking. The baked biscuits are cooled to a certain temperature and then sprayed with atomized oil to enhance the taste and color of the biscuits. The fuel injection amount is usually 5%-10% and can be adjusted according to needs.

●Cooling and Arranging: The baked biscuits cannot be packaged immediately. At this stage, the biscuits are cooled to room temperature through a cooling conveyor belt to prevent moisture accumulation, which may lead to moisture. After cooling, the biscuits are arranged neatly using an automated sorting system.

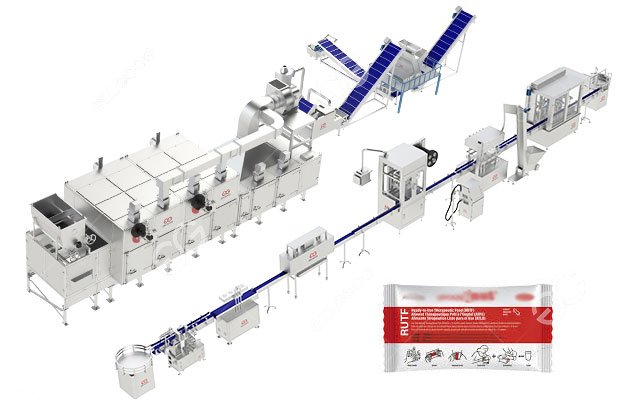

●Biscuit Packaging: Packaging is the final step in the biscuit production process. Modern biscuit line is equipped with packaging machinery capable of packaging biscuits in various materials such as plastic, foil or paper. The automated packaging system not only ensures the freshness and shelf life of the biscuits but also facilitates efficient distribution and retail display.

Video of Industrial Biscuit Production Line

Advantages of Biscuit Processing Line

♦Multiple Purposes: The biscuit line can accommodate a wide range of biscuit types, sizes, and shapes. Manufacturers can easily switch between different biscuit products with minimal adjustments, allowing for greater product diversity.

♦Cost Efficiency: Despite the initial investment in machinery, industrial production lines are cost-effective in the long run. They reduce labor costs, minimize material waste, and optimize energy usage, resulting in overall cost savings.

♦Customization: Automatic industrial biscuit production lines are highly customizable to meet specific production requirements. Manufacturers can tailor the equipment to produce biscuits with unique flavors, textures, and designs.

♦Wide range of production capabilities: This equipment can not only process large-volume biscuits, but also produce biscuits with small and medium-sized capacities. The production capacity range is 100-1200 kilograms per hour. Biscuit manufacturers are able to meet the high market demand efficiently.

Industrial biscuit production lines have revolutionized the biscuit manufacturing industry by increasing efficiency, consistency, and production capacity. These state-of-the-art systems have allowed for a wider range of biscuit varieties to meet the diverse tastes of consumers worldwide. As technology continues to advance, we can expect even more innovation in biscuit production, catering to evolving consumer preferences while maintaining the deliciousness and quality we associate with biscuits.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online