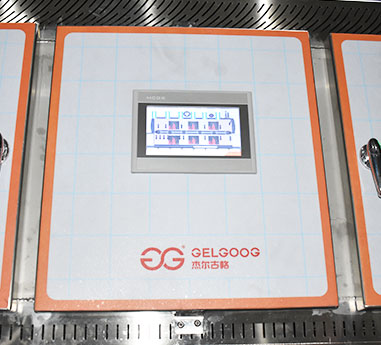

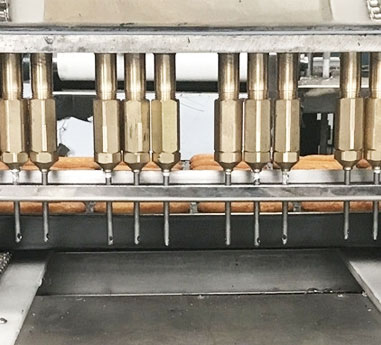

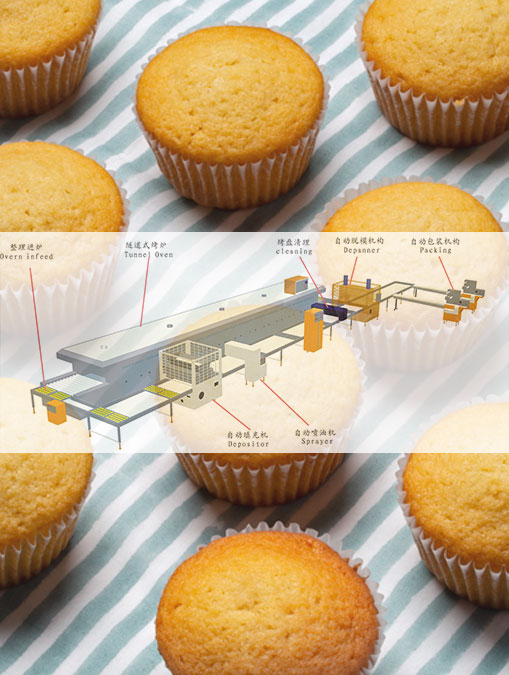

1 The cake forming adopts fully automatic program control, which can quickly change product varieties, touch screen operation interface, and parameter settings are clear at a glance.

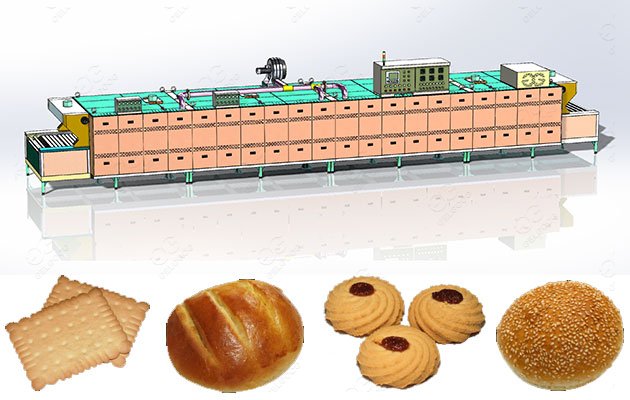

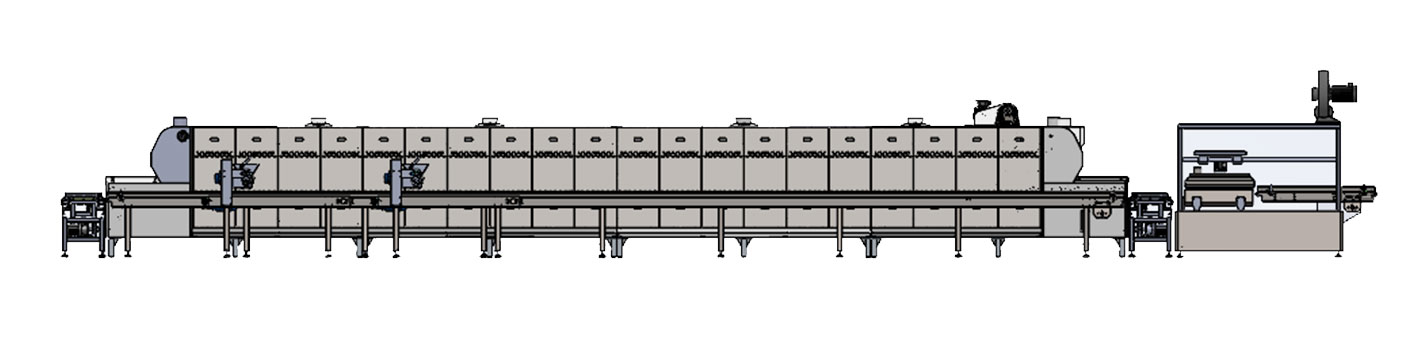

2 Tunnel ovens include electric ovens, gas direct-fired ovens, gas hot-blast ovens, different energy options, and different heat conduction methods to meet the requirements of different products.

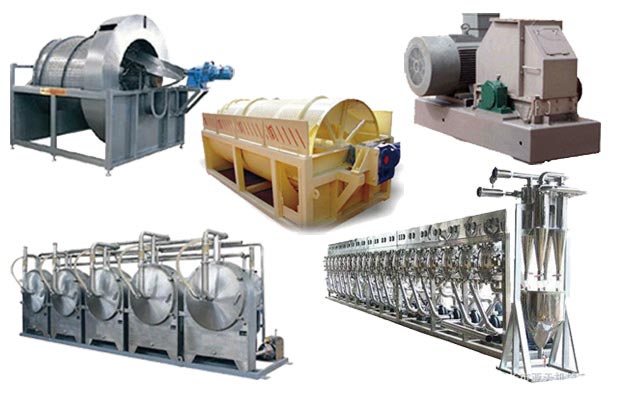

3 Rich experience in production line matching, each with different types of automatic/semi-automatic production lines, according to customer requirements and actual conditions, tailor-made the most suitable production line for customers.

4 Cake processing process: raw material mixing → automatic feeding → mold injection → grouting forming → baking → cooling → demoulding → sterilization → returning to tray → winding up.

Русский язык

Русский язык