This fruit washing waxing and grading solution is mainly to satisfy the customers for the primary processing of the main ball and ellipsoid fresh fruits. It mostly contains a series of operation processes such as elevator fruit discharge, brush cleaning, brush air drying, waxing, hot air drying, grading, etc., to realize the pre-treatment processing of fresh fruits.

In addition, according to the characteristics of different fruits, different equipment can be customized, such as apples and other easy-to-bruise materials, the use of non-fruit-touching cleaning and conveying methods, from the mechanical structure to minimize material damage. At the same time, after the classification can be with the customer demand, using the diameter, weight classification, and even the appearance, internal quality inspection, etc., to achieve higher classification needs.

Features of Fruit Washing Waxing and Grading Processing Solution

1 Compared with the traditional large pool cleaning method, this solution saves more water resources.

2 Each process corresponds to one device, and each device can be quickly disassembled, which is easy to install and maintain.

3 Customize different conveying methods according to the characteristics of each fruit to minimize the fruit damage rate.

4 Automatic loading of graded materials, no manual assistance required, saving costs.

5 Various grading methods of fruit washing waxing and grading solution can be customized according to customer needs.

6 The entire line material is available in full 304 and carbon steel spraying (304 for the part in contact with the material).

What Can We Do ?

Customize Your Product Needs for You

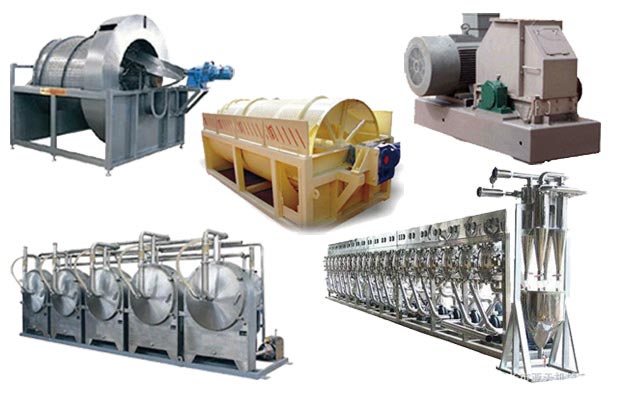

Single Machine in the Processing Solution

Please fill in the form below to get a free quote. We will get back to you within 12 hours.

Русский язык

Русский язык