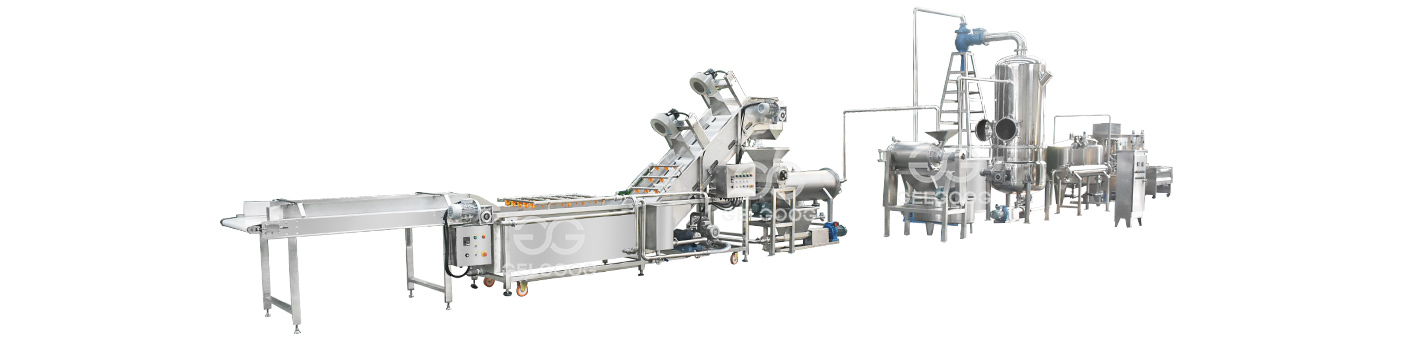

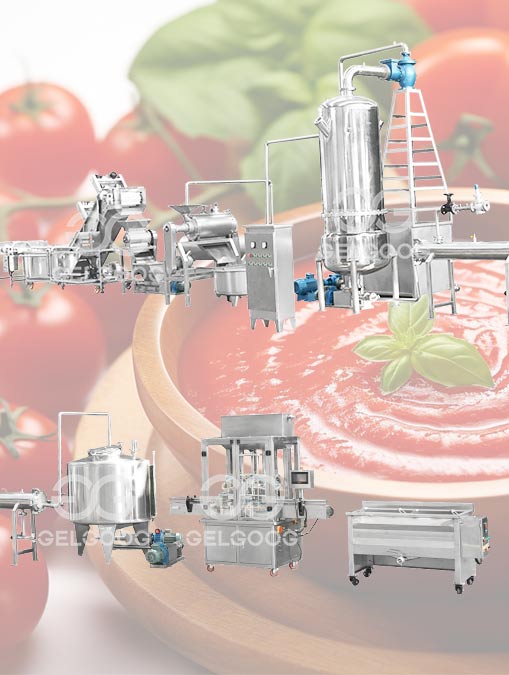

1 From the cleaning, peeling, seeding, and pulping of raw materials to the final filling and sealing, the entire production process is highly automated, which improves production efficiency.

2 Different yields and packaging forms can be customized according to user needs. The entire line equipment layout and control method can be customized according to customer site and operation requirements.

3 Equipped with advanced control systems, it can precisely control key parameters such as temperature, pH value, concentration, etc. during the production process to ensure the consistency and stability of product quality.

4 The solution can be adjusted according to different product requirements to produce tomato pastes of different flavors and concentrations.

Русский язык

Русский язык