Efficient Cookie Production Line for Biscuit Industry

Output:300KG/H

Output:300KG/H Voltage:380V

Voltage:380V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

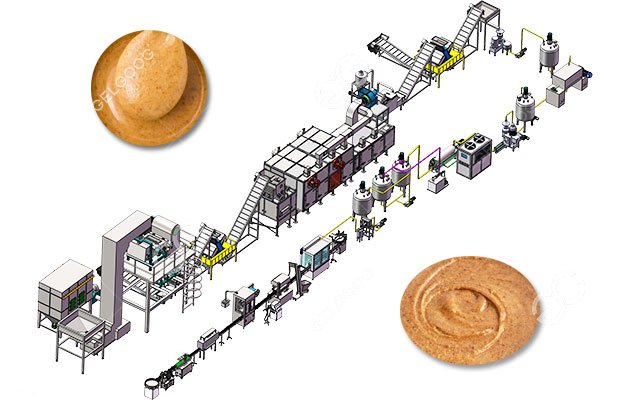

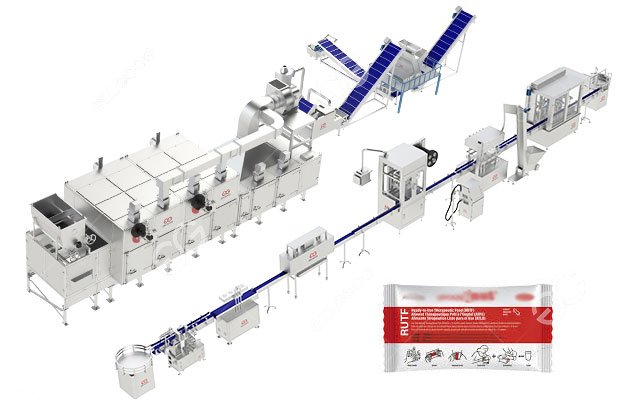

The cookie production line is a mechanized production line used to produce cookies of various flavors. The production line consists of multiple steps, including forming, baking, cooling, packaging, etc.

The following is the main process of the production line: raw material preparation--biscuit molding---baking---oil spraying---cooling---finishing---packaging.

- Raw Material Preparation: Raw materials will be sent to the ingredients area for screening, mixing and other operations to ensure the quality and hygiene of the raw materials.

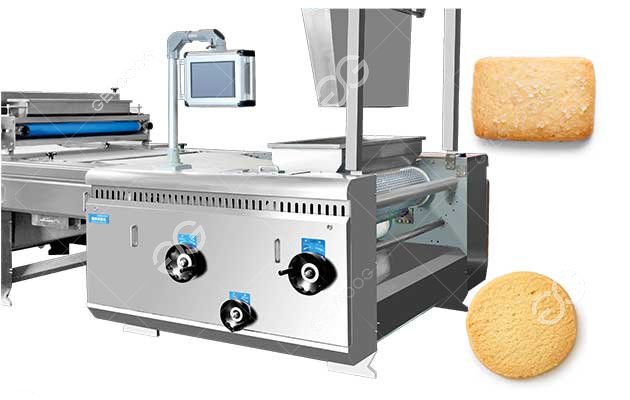

- Cookies Forming: Pour the mixed raw materials into a dough mixer to form cookie dough, and then go through processes such as extrusion, shaping, and shaping of the mold to form cookies of various shapes.

- Baking: Move the shaped cookies to the oven and bake them at high temperatures to bake them until golden brown on the surface and cooked inside.

- Cooling: Place the baked cookies on the cooling conveyor belt, and gradually reduce their temperature through natural cooling or air cooling to reach the appropriate packaging temperature.

- Packaging: Put the cooled cookies into packaging bags or boxes, seal them, and label them with information such as production date to ensure their freshness and hygienic safety.

The automatic cookie production line is an efficient and automated production line with the following characteristics:

- Continuous production: This equipment is a continuous production line, which can achieve uninterrupted production to meet the large demand of the market.

- Automated production: It uses automated technology, including automated transportation, packaging, assembly and quality inspection, reducing manual operations and improving production efficiency and quality.

- Multi-style production: The industrial cookie processing line can produce a variety of biscuits and cookies of different flavors, shapes and sizes. One set of equipment can meet the diverse needs for biscuits in the market.

- Customized production: The automated production line can be customized according to customer requirements. In addition, it can also provide services such as mature biscuit recipes and factory planning.

- Energy saving and environmental protection: The cookie making machine adopts advanced energy saving and environmental protection technologies, such as energy recovery, wastewater treatment, etc., to reduce energy consumption and environmental pollution.

- Flexibility: The equipment has high flexibility and can be adjusted and improved according to the production needs of cookies to improve production efficiency and quality.

Video of Industrial Cookie Production Line

The maintenance of cookie equipment is very important to ensure the normal operation of the equipment and extend its service life. The following are some maintenance suggestions for industrial cookie production lines:

- Clean the equipment regularly: Dust, dirt, and debris can be removed from the surface of the equipment to ensure that the surface of the equipment is clean. Additionally, cleaning your equipment can help identify and fix potential problems in your equipment.

- Check and replace wearing parts: Wearing parts on the production line include belts, bearings, gears, etc. Regularly check the wear of these wearing parts. If the wear is serious, they need to be replaced in time.

- Lubricating equipment: It can help reduce equipment wear and extend equipment life. It is recommended to use appropriate lubricant and follow the instructions on the production line for lubrication.

- Check the safety of the equipment: The equipment in the cookie processing line may have safety hazards, such as belts falling off, gears loosening, etc. Regularly check the safety of your equipment and fix potential problems promptly.

- Regularly check the operating status of the equipment: Regularly check the operating status of the equipment, such as temperature, pressure, vibration, etc. If an abnormality is found, it needs to be handled in time.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online