Food machinery industry demand should the situation change

2016-09-20 by admin

"Green Manufacturing Engineering Implementation Guide" published food machinery industry demand should the situation change

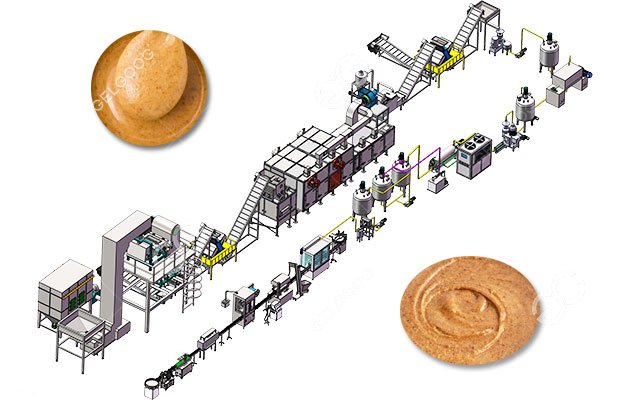

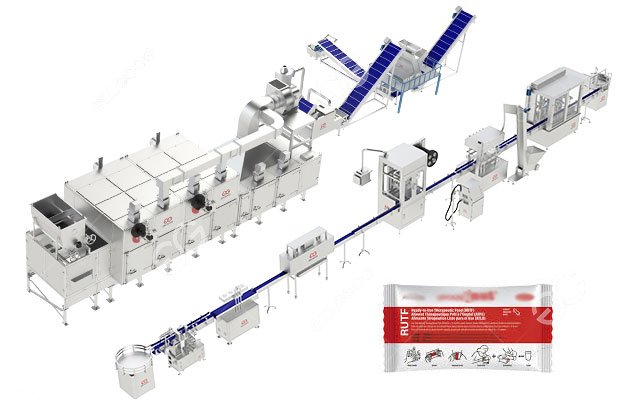

Recently, the Ministry of Information Industry and other four departments jointly issued the "Green Manufacturing Engineering Implementation Guide (2016-2020)." "Guide" clearly highlights the green, energy saving, emission concept, which the food industry, machinery and equipment required should the situation change, closely follow the development in the trend of manufacturing, to achieve the high energy consumption, high emission, high investment product the upgrading.

"Green Manufacturing Engineering Implementation Guide" published food machinery industry demand should the situation change

"Guide" states that China's manufacturing industry in the whole industry chain of low-end, low value-added products, compared to the United States, Germany, Japan and other developed countries, the high consumption of resources and energy products, the impact on the ecological environment to highlight the urgent need to accelerate green development, to change the traditional model of development of high input, high consumption, high emission, build a green manufacturing system.

September 19, the Ministry of Energy Saving and Comprehensive Utilization Department responsible person in an interview with reporters, said the goal is to establish a manufacturing green manufacturing system of green low-carbon development cycle, "green transformation of traditional manufacturing demonstration" "Resource Recycling use of green demonstration and application development, "" green manufacturing technology innovation and industrialization demonstration application "" green manufacturing system pilot Program ", etc. will be an important measure to achieve this goal.

"Green manufacturing engineering is a key measure of manufacturing industry 'green' development, manufacturing transformation and upgrading is the only way." Secretary for Energy Saving and Comprehensive Utilization of the Ministry of Gao Yun Hu said that the implementation of green manufacturing, is through technological innovation and systems optimization, green design, green technologies and processes, green production, green management, green supply chain, green recycling and other concept throughout the product life cycle, environmental impact and the whole industry chain of minimum resources and energy efficiency the highest obtained coordination of economic, ecological and social benefits of optimization.

In traditional manufacturing demonstration green transformation, the "Guide" proposed to implement clean production process transformation, energy efficient low-carbon transformation, transformation and utilization of water resources and efficient manufacturing process based green transformation. Ministry will focus on the promotion in the iron and steel, nonferrous metal, ferroalloy, petrochemical, chemical, cement, paper and other industries of raw materials optimization, energy cascade utilization, recycling, process reengineering system optimization technology; around the chemical, steel, paper, printing, food and drug high-water industry, the use of water balance and optimize the overall system solutions, such as water-saving technologies.

According to reports, "Thirteen Five" period, around the green development of industrial recycling of resources, the Ministry of Industry focus will be undertaken to strengthen comprehensive utilization of resources, promote green industry collaborative links, foster remanufacturing industry and so on. Make industrial, agricultural and domestic development of effective combination, to explore the development of new cross-sectoral cooperation cycle development model. Strive to 2020, the remanufacturing process technology has reached the international advanced level, remanufacturing industry reached 200 billion yuan.

Gao Yun Hu said the focus on green manufacturing technology innovation and industrialization demonstration application that equipment, including energy-saving breakthrough in key technology and equipment, enhance the development of major environmental protection technology and equipment, and comprehensive utilization of resources and applicable technologies and equipment. In the economizer, energy saving, recycling of residual energy, efficient energy storage, intelligent control and other areas to increase R & D and demonstration efforts to foster a number of core competitiveness of key enterprises, breaking the 40 major energy-saving technologies with independent intellectual property rights equipment.

Gao Yun Hu also revealed that, at present, industrial products and green design mechanisms to promote green product evaluation standard system has been initially established, the list of 11 green design products have been evaluated released four green national standards, 13 standards have been published groups. The next step will accelerate green product standards, and strengthen the implementation of the standards.

Recently, the Ministry of Information Industry and other four departments jointly issued the "Green Manufacturing Engineering Implementation Guide (2016-2020)." "Guide" clearly highlights the green, energy saving, emission concept, which the food industry, machinery and equipment required should the situation change, closely follow the development in the trend of manufacturing, to achieve the high energy consumption, high emission, high investment product the upgrading.

"Green Manufacturing Engineering Implementation Guide" published food machinery industry demand should the situation change

"Guide" states that China's manufacturing industry in the whole industry chain of low-end, low value-added products, compared to the United States, Germany, Japan and other developed countries, the high consumption of resources and energy products, the impact on the ecological environment to highlight the urgent need to accelerate green development, to change the traditional model of development of high input, high consumption, high emission, build a green manufacturing system.

September 19, the Ministry of Energy Saving and Comprehensive Utilization Department responsible person in an interview with reporters, said the goal is to establish a manufacturing green manufacturing system of green low-carbon development cycle, "green transformation of traditional manufacturing demonstration" "Resource Recycling use of green demonstration and application development, "" green manufacturing technology innovation and industrialization demonstration application "" green manufacturing system pilot Program ", etc. will be an important measure to achieve this goal.

"Green manufacturing engineering is a key measure of manufacturing industry 'green' development, manufacturing transformation and upgrading is the only way." Secretary for Energy Saving and Comprehensive Utilization of the Ministry of Gao Yun Hu said that the implementation of green manufacturing, is through technological innovation and systems optimization, green design, green technologies and processes, green production, green management, green supply chain, green recycling and other concept throughout the product life cycle, environmental impact and the whole industry chain of minimum resources and energy efficiency the highest obtained coordination of economic, ecological and social benefits of optimization.

In traditional manufacturing demonstration green transformation, the "Guide" proposed to implement clean production process transformation, energy efficient low-carbon transformation, transformation and utilization of water resources and efficient manufacturing process based green transformation. Ministry will focus on the promotion in the iron and steel, nonferrous metal, ferroalloy, petrochemical, chemical, cement, paper and other industries of raw materials optimization, energy cascade utilization, recycling, process reengineering system optimization technology; around the chemical, steel, paper, printing, food and drug high-water industry, the use of water balance and optimize the overall system solutions, such as water-saving technologies.

According to reports, "Thirteen Five" period, around the green development of industrial recycling of resources, the Ministry of Industry focus will be undertaken to strengthen comprehensive utilization of resources, promote green industry collaborative links, foster remanufacturing industry and so on. Make industrial, agricultural and domestic development of effective combination, to explore the development of new cross-sectoral cooperation cycle development model. Strive to 2020, the remanufacturing process technology has reached the international advanced level, remanufacturing industry reached 200 billion yuan.

Gao Yun Hu said the focus on green manufacturing technology innovation and industrialization demonstration application that equipment, including energy-saving breakthrough in key technology and equipment, enhance the development of major environmental protection technology and equipment, and comprehensive utilization of resources and applicable technologies and equipment. In the economizer, energy saving, recycling of residual energy, efficient energy storage, intelligent control and other areas to increase R & D and demonstration efforts to foster a number of core competitiveness of key enterprises, breaking the 40 major energy-saving technologies with independent intellectual property rights equipment.

Gao Yun Hu also revealed that, at present, industrial products and green design mechanisms to promote green product evaluation standard system has been initially established, the list of 11 green design products have been evaluated released four green national standards, 13 standards have been published groups. The next step will accelerate green product standards, and strengthen the implementation of the standards.

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык