Automatic Lumpia Wrapper Maker Machine 0.3-1MM Thickness

Output:

Output: Voltage:

Voltage: Power:

Power:  Payment Method:

Payment Method:

Features

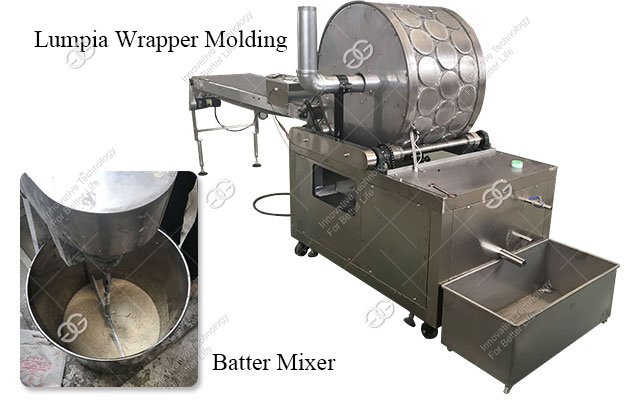

Description of Lumpia Wrapping Machine

This type spring roll machine can produce a spring roll of the same thickness of 0.3mm---0.8mm, and the thickness of lumpia wrapper contr of 10-50cm.

This series lumpia wrapper machine has two models, customers can choose according to different needs. Lumpia wrapper machines of different sizes and different yields can also be customized according to user needs.

Working Video of Lumpia Wrapping Machine

This type spring roll machine can produce a spring roll of the same thickness of 0.3mm---0.8mm, and the thickness of lumpia wrapper contr of 10-50cm.

This series lumpia wrapper machine has two models, customers can choose according to different needs. Lumpia wrapper machines of different sizes and different yields can also be customized according to user needs.

Principle of Lumpia Wrapper Maker Machine: According to the requirements of the surface preparation process, the dough is prepared, and the dough is heated and baked by a round roasting wheel to become a fixed thickness spring roll or other sheet-like food.

Process of Lumpia Wrapper Machine: Put the prepared dough into the bucket, when the baking wheel is heated to 160 °C; start the slurry pump to send the slurry to the nozzle, operate the clutch lever, and make the paste adhere to the arc of the baking wheel.

On the surface, when the roasting wheel rotates at an angle of 270-300 degrees, the dough is matured and automatically separated from the roasting wheel to form a fixed thickness spring roll or an instant roll spring roll.

On the surface, when the roasting wheel rotates at an angle of 270-300 degrees, the dough is matured and automatically separated from the roasting wheel to form a fixed thickness spring roll or an instant roll spring roll.

Working Video of Lumpia Wrapping Machine

The Features of Lumpia Wrapping Machine

1. Adopt advanced temperature control system to make temperature control error-free, no heat waste, and achieve energy saving.

1. Adopt advanced temperature control system to make temperature control error-free, no heat waste, and achieve energy saving.

2. Lower production cost, simple operating system, one person can operate, saving labor.

3. Heating method of the roasting wheel: electric heating row or gas heating.

4. The lumpia wrapper maker machine is made of stainless steel and is clean and hygienic.

Technical Data

| Model | GG-5029 | GG-8045 |

| Dimension | 4.7*0.95*1.58m | 5.2*1*1.5m |

| Power | 13.2 kw | 38kw |

| Host Power | 0.75 kw | 0.75 kw |

| Power Cutter | 0.55 kw | 0.55 kw |

| Belt Power | 0.55 kw | 0.55 kw |

| N. W. | 800kg | 1000 kg |

| Thickness | 0.3-1.0mm | 0.3-1.0mm |

| Capacity | 1000-1600pcs/h | 3500pcs/h |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online