Commercial New Ramen Noodle Making Machine 300KG/H

Output:

Output: Voltage:

Voltage: Power:

Power:  Payment Method:

Payment Method:

Features

The Introduction of Ramen Noodle Making Machine

It is a new type of noodle processing equipment, can work continuously from feeding to finished product. The ramen noodle machine has the advantages of high output, high efficiency, time and labor saving, easy operation, etc. Can be used to produce noodles of different specifications, such as noodles, egg noodles, vegetable noodles, colored noodles, etc., the produced noodles have good toughness and good taste.

Characters of Commercial Ramen Noodle Machine

Testing Video of New Designed Ramen Noodle Maker

It is a new type of noodle processing equipment, can work continuously from feeding to finished product. The ramen noodle machine has the advantages of high output, high efficiency, time and labor saving, easy operation, etc. Can be used to produce noodles of different specifications, such as noodles, egg noodles, vegetable noodles, colored noodles, etc., the produced noodles have good toughness and good taste.

Characters of Commercial Ramen Noodle Machine

- The noodle making machine is made of food grade materials, and the noodles produced are hygienic and safe.

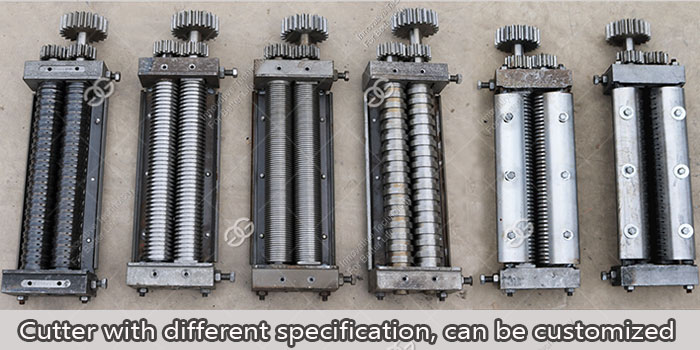

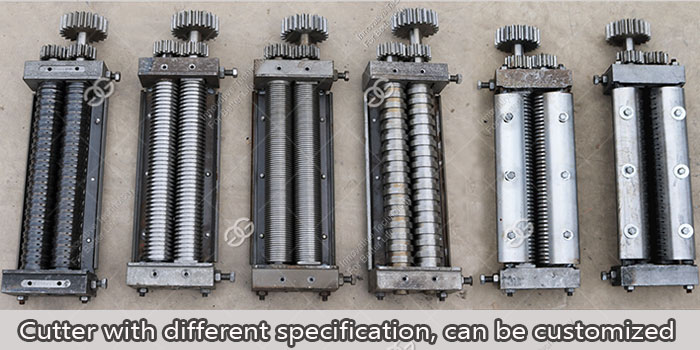

- There are many specifications for the cutters, and each machine can be equipped with different cutters to make types of noodles.

- This ramen noodle maker machine with automatic continuous extension, automatic cutting, automatic section and other functions.

- Noodles do not stick to the knives, and the length of the noodles can be adjusted according to customer needs.

- This commercial ramen noodle maker mainly used for commercial use, the output can reach 250-300 kilograms per hour.

Testing Video of New Designed Ramen Noodle Maker

The conventional voltage of the noodles machine is 380V 50hz, which can be changed according to the local usage of the customer. Besides, each machine is equipped with different tools, common tools are divided into flat and round knives, regular size is below.

Flat knife: 0.75mm, 1mm, 1.25mm, 1.5mm, 1.75mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 20mm.

Round knife: 1.25mm, 1 5mm, 1.75mm, 2mm, 2.5mm.

How to Install Noodle Cutter?

The left and right grid plates are provided with two sipe, the noodle knives are placed in the slots, and the gears on the noodle knives are engaged with the large gears, and the butterfly nut is tightened by the fixing bracket to fix the noodle knives. Then, the end of the dough piece is placed into the two-roll gap in the rotation by hand, and after rolling again, the noodle knife is cut and the noodle is cut out.

Technical Data

| Model | GG7-300 |

| Capacity | 250-300kg/h |

| Power | 4KW |

| Size(MM) | 2900*750*1370 |

| Weight(KG) | 750 |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online