Fried Instant Noodle Production Line|Instant Noodles Making Machine

Output:

Output: Voltage:

Voltage: Power:

Power:  Payment Method:

Payment Method:

Features

Introduction of Fried Instant Noodle Production Line

Automatic instant noodle production line, with perfect technology, compact structure, original design and stable performance, is developed on the base of previous products and requirement in the world market. It realizes high automation, convenient operation, low energy and small floor space, that assures all working procedures from feeding flour to finished products can be accomplished once.

The features of instant noodles making machine

Automatic instant noodle production line, with perfect technology, compact structure, original design and stable performance, is developed on the base of previous products and requirement in the world market. It realizes high automation, convenient operation, low energy and small floor space, that assures all working procedures from feeding flour to finished products can be accomplished once.

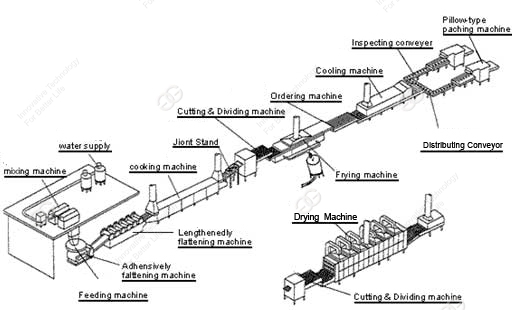

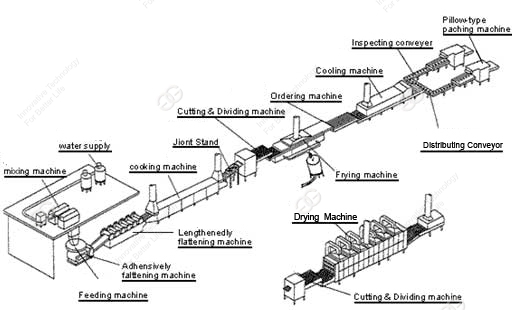

Flow Chart of instant noodles processing plant:

The Production flow chart: wheat flour, dressing mixer →curing machine →Composite continuous rolling→steamed noodles → frame cutting→folding → deep fry → cooling → packing.

Application of fried instant noodle production line:

Whole instant noodle production line to make the instant noodles. Welcome to our company, we will take you around our production department, and check the machines.

Whole instant noodle production line to make the instant noodles. Welcome to our company, we will take you around our production department, and check the machines.

This instant noodle plant is highly automatic, convenient, low energy consumption and less space occupation, all these features assure this line suitable to small-sized or self-owned enterprises.The corrugated instant noodle produced by this line is strength, smooth and transparent. It is very easy to be saturated by water.

The features of instant noodles making machine

1. Sophisticated process, compact structure, novel design, stable and reliable performance;

2. A complete production from the flour to the finished product by one time;

3. High automatic degree, simple operation, moderate production;

4. energy-saving, less premise, less investment, quick effect.

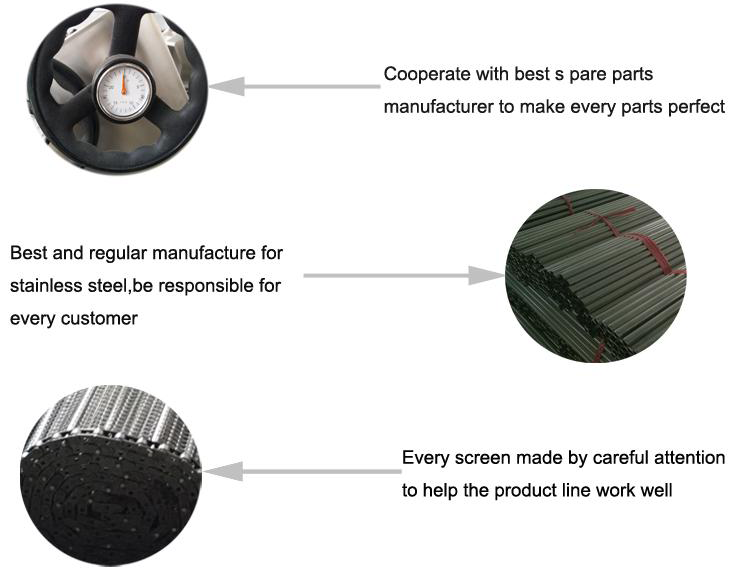

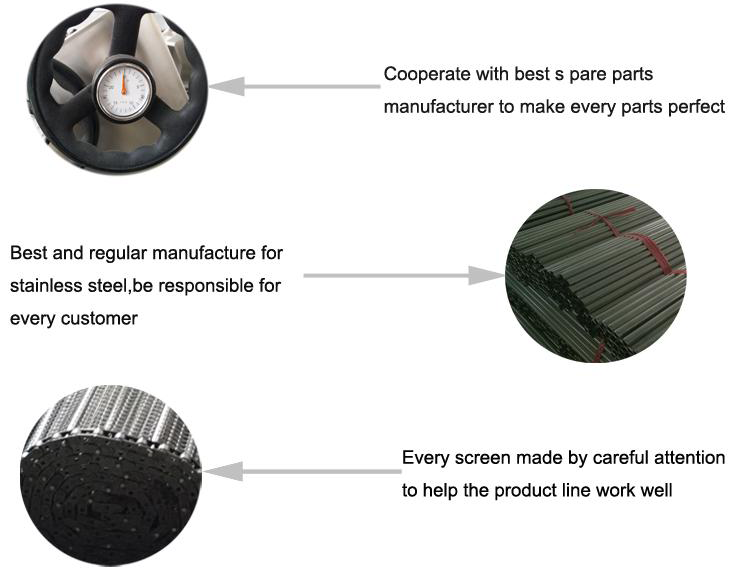

Instant Noodle Production Line Factory Introduction

Henan GELGOOG Machinery Co., Ltd., founded in 2010, is an independent manufacturer for developing, manufacturing and selling food machinery. The instant noodle production line is one of our main equipment. The quality of the product is guaranteed. Our products are mainly exported to more than 30 countries and regions, such as Europe, America, Asia, Middle East, Africa and so on. Our machinery for its advanced technology and high reputation all over the world. For many years, the GELGOOG people insist on the management idea of innovative management and refinement, let customer satisfaction be the tenet and constantly develop and create new products. With his strong strength and high reputation, it has won the trust of many customers in China and the world.

The price of instant noodles production line if you want to know, please email lisa@machinehall.com, skype: jacobyaogelgoog, tell us your requirement, then we will send you machine price and details.

Instant Noodle Production Line Factory Introduction

Henan GELGOOG Machinery Co., Ltd., founded in 2010, is an independent manufacturer for developing, manufacturing and selling food machinery. The instant noodle production line is one of our main equipment. The quality of the product is guaranteed. Our products are mainly exported to more than 30 countries and regions, such as Europe, America, Asia, Middle East, Africa and so on. Our machinery for its advanced technology and high reputation all over the world. For many years, the GELGOOG people insist on the management idea of innovative management and refinement, let customer satisfaction be the tenet and constantly develop and create new products. With his strong strength and high reputation, it has won the trust of many customers in China and the world.

The price of instant noodles production line if you want to know, please email lisa@machinehall.com, skype: jacobyaogelgoog, tell us your requirement, then we will send you machine price and details.

Technical Data

| No | Equipments | Model | Quantity | Remark |

| 1 | Brine metrology mixer | GGYSH100 | 2set | 1.5 kw, Pump power 0.75 kw, the capacity of 1000 l/units, contact with water for stainless steel surface |

| 2 | Supply metering device | GGYSJ10 | 1set | Volume of 110 liters with LCD, round of tank, stainless steel, the pump is 0.75 kw, |

| 3 | Double speed dough mixer | GGHMJ200 | 2set | power 9/11kw, 200 kg/pan, manually open the door, contact with the surface of stainless steel and nylon |

| 4 | Disc curing machine | GGXS200 | 1set | Power 4 kw, Tray 2000 mm x 410 mm and raw material for stainless steel surface contact |

| 5 | Single continuous rolling machine | GGMT9-80 | 1set |

Paste width 510, 7.5+11=18.5kw power(Frequency control of motor speed), 9 pcs steel roller, Hands + worm mechanism adjustable thickness, roll diameter φ395×1、φ300×2, φ248×2, φ180×2, φ162×2 |

| 6 | Single-layer steamed noodles machine | GGCZM63 | 1set |

Machine is 28 meters long, 3 kw power (VVVF), fan 0.37 kw x 2 units, water seal, mechanical lifting door, stainless steel |

| 7 | Cutting and folding machine | GGQF120 | 1set |

Main drive 1.5 kw (frequency control of motor speed),air knife:0.9 kw, With spray device. |

| 8 | Fried dryer | GGYZ100 | 1set |

Main drive 3 kw (VVVF), Lift 2.2 kw,Circulating pump 11 kw ,Gear pump 2.2 kw, 0.9 kw wind knife x 2 reached m2, spiral plate heat exchanger 1, 1 set 3.5 m3 tank , carbon steel |

| 9 | Air cooling device | GGFL120 | 1 set | Blower: 0.37 kwx14 sets, exhaust fan 3 kw power supply by Fried, carbon steel plastic sheeting |

| 10 | Shunt conveyor | GGFS120 | 1 set | Main drive 1.1 kw (VVVF), |

| 10 | Conveyor | GGSS120 | 3set | 0.37 kw x 3 main drive, mechanical control, stainless steel panel |

| 11 | Products conveyor | GGCS120 | 3set | w x 2 main drive, mechanical control, stainless steel panel |

| 12 | Electric control cabinet | GGBPT-1 | 1 set | The main process adopts frequency control of motor speed, PLC program control |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Skype:jacobyaogelgoog

Skype:jacobyaogelgoog Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online