Features

Usefulness:

Clean and carry potatos to Cage Washer.

Clean and carry potatos to Cage Washer.

Features:

Driven by speed adjustable motor, flow rate can be automatic from long-distance.

Driven by speed adjustable motor, flow rate can be automatic from long-distance.

Material:

carbon steel,stainless steel

carbon steel,stainless steel

In the production of potato starch, potato washing is a very important step, it is directly on the quality of starch plays a key role, because it is not clean, once into the starch slurry, it will give a lot, after purification processes inconvenience, the starch production increases costs, production of starch grades decline, prices are correspondingly reduced. I produced a spiral cleaning conveyor, has a small footprint, stable and reliable operation, long life and other characteristics.

1. The machine structure

There are spiral elevator, housings, water pipes, sewage hole, transmission components.

2. Use of cleaning principle and machinery Cleaning and transporting raw potato to clean the cage. Remove fresh potato weeds, stones and other impurities into the lower part of the machine uniformly by the screw conveyer elevator liter, in this process, fresh potato in the machine rolling friction, even under water erosion, soil and fresh potato isolated discharged from the sewage hole, to achieve the purpose of washing, fresh potato discharged from the upper blanking mouth.

3. Machine features

Spindle no suspension device to ensure the smooth transportation of the material, frequency control, which enables remote automatic flow control; according to the actual supply and raspers the work of the feed material and the material adjusted accordingly; stable performance, smooth; spout with a flapper valve, adjustable raspers feed in conveyor length based on the actual material transport length.

Technical Data

|

Model |

Output (kg/h) |

Power (kw) |

Outer size (mm) |

| GSS30 | 3000 | 3 | 4500 x 450 x 800 |

| GSS35 | 4000 | 4 | 4500 x 560 x 900 |

| GSS45 | 5000 | 5.5 | 5200 x 700 x 1000 |

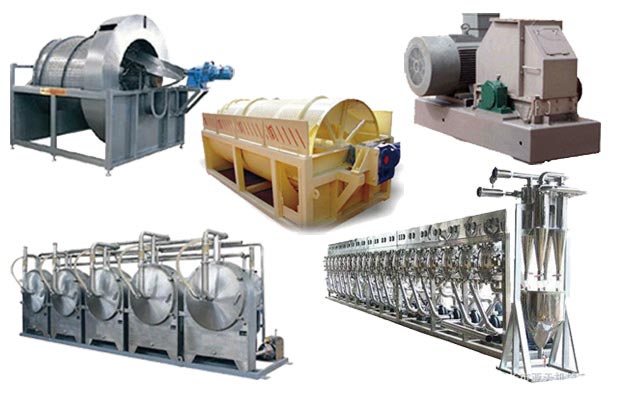

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Skype:jacobyaogelgoog

Skype:jacobyaogelgoog Русский язык

Русский язык

Output:

Output:

Get Price

Get Price Chat Online

Chat Online