Dubai Date Palm Washing Sorting Packaging Project

2025-08-08 by Lisa

The successful delivery of the Dubai date palm washing sorting packaging project demonstrates GELGOOG's expertise, setting a new benchmark in the food processing industry and earning the trust of Dubai customers.

The date plam project combines advanced automation technology with stringent quality control measures, ensuring that every date is meticulously cleaned, accurately sorted, and hygienically packaged.

Date Palm Project Description

On August 6, 2025, GELGOOG's date palm washing, sorting, and packaging project in Dubai successfully passed inspection, marking the official start of production. The project covers multiple stages, including impurity removal, washing, drying, sorting, and packaging.

To address the unique characteristics of date palm, the project introduced impurity removal features, utilizing vertical brushes and atomized spraying systems to effectively reduce surface damage, enhance cleaning efficiency, and protect the fruit skin.

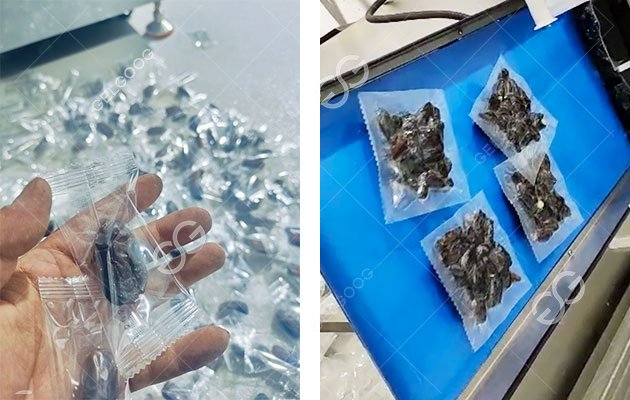

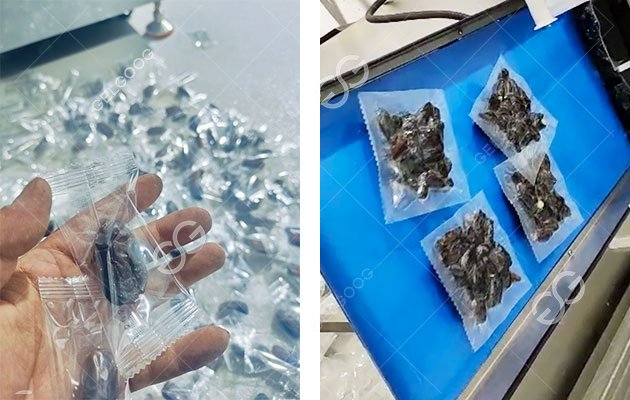

The drying equipment efficiently removes moisture, while the sorting system ensures that each date palm meets quality standards. Packaging options include stretch film packaging for bulk transport and individual packaging for retail markets, catering to diverse market needs.

Advantages of Dubai Date Palm Washing Sorting Packaging Project

- Efficient Automated Production: Advanced automated cleaning, sorting, and packaging equipment are used to significantly improve processing efficiency and reduce labor costs.

- Precise Intelligent Sorting: The date palm project is equipped with AI visual recognition and optical sorting technology to accurately detect the size, color, and defects of dates, achieving high grading accuracy and more consistent quality.

- Strict Hygiene and Safety Control: The entire process complies with international food safety standards (such as HACCP and ISO 22000), ensuring a pollution-free and impurity-free environment, meeting the demands of the high-end market.

- Energy-Saving and Environmentally Friendly Design: A circulating water cleaning system and energy-saving equipment are used to reduce water and energy consumption, lower carbon emissions, and align with sustainable development trends.

- Flexible Customization: The project supports personalized packaging (such as vacuum packaging and gift box packaging) and production line expansion to meet diverse customer needs and enhance market competitiveness.

With high automation, water and energy savings, and remarkable professionalism and efficiency, the production line has earned high praise from clients.

The successful acceptance of this dubai date palm washing sorting packaging project showcases GELGOOG's technological advantages and innovative capabilities in the food processing field, providing clients with more efficient and high-quality production solutions.

Looking ahead, GELGOOG remains committed to providing intelligent food processing equipment to global clients, driving continuous innovation and development in the industry.

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык