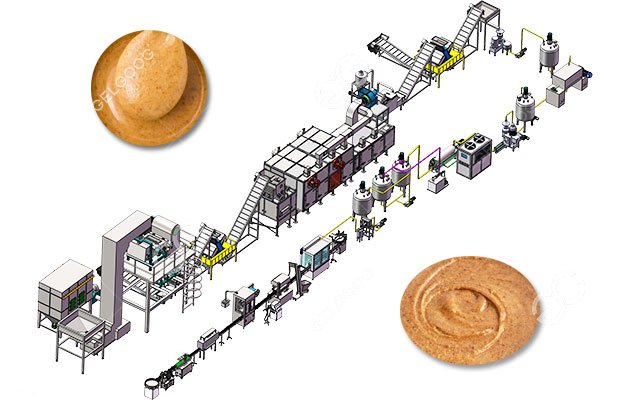

Fully Automatic Biscuit Production Line 100-1200KG/H

Output:100-1200KG/H

Output:100-1200KG/H Voltage:380V

Voltage:380V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

The automatic biscuit production line is mainly for making a wide variety of biscuits on a large scale. With a capacity ranging from 100 to 1200 KG/H, it caters to different production demands in the bakery industry.

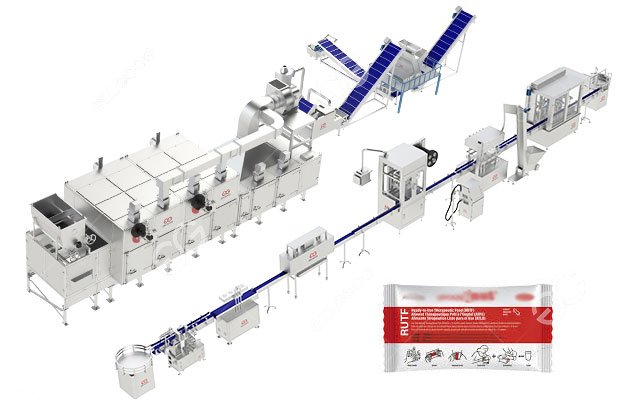

This production line integrates multiple advanced technologies and equipment, including dough mixing, shaping, baking, cooling, and packaging systems, ensuring a smooth and continuous production process.

Automatic Biscuit Production Line Features

- Flexible production: The line can quickly switch between different biscuit recipes and production modes. It can easily adapt to small batches of customized orders as well as large scale standardized production, providing clients with greater flexibility to meet market demands.

- Quality control: Equipped with advanced quality detection systems like automatic weight checkers and metal detectors, the production line can monitor and control product quality in real - time. This ensures that every biscuit meets high - quality standards before leaving the factory.

- Durable and reliable: Made of high - quality materials and components, the equipment has excellent wear - resistance and stability. With a long service life, it reduces equipment replacement costs for clients and ensures continuous and stable production.

- Compact design: The automatic biscuit production line has a compact layout that saves space. It’s ideal for clients with limited factory space, enabling efficient production without compromising output.

- Environmental friendly: The equipment adopts effective dust - collection and noise - reduction measures, minimizing environmental pollution during production. This helps clients meet environmental regulations and standards, enhancing their corporate image.

Process of Making Biscuits in a Factory

- Dough mixing: Start using this industrial biscuit production line, the first step is select the ingredients like flour, sugar, and butter as per the recipe. The dough mixer blends them into uniform dough by controlling mixing time and speed.

- Biscuit Forming: Then, biscuit forming machine forms the dough into desired biscuit shapes such as round or square. This step is crucial for the appearance of the final product.

- Biscuit Baking: Next, the shaped dough pieces are baked in the tunnel oven at a regulated temperature for the required time. During this process, the dough transforms into golden and crispy biscuits.

- Biscuit Cooling and Packing: After baking, the biscuits need to be cooled to a suitable temperature to maintain the taste and appearance. Finally, the automatic packaging machine packs the cooled biscuits to extend the shelf life.

Automatic Biscuit Production Line Application

For large scale food processing enterprises, we provide high capacity equipment with outputs exceeding 1000KG/H. These lines can efficiently meet the massive production demands of large companies, helping them achieve economies of scale and enhance market competitiveness.

For medium and small sized enterprises, our production lines are available in capacities ranging from 100-500KG/H. These models are more flexible and better suited to the production scales of smaller businesses. They allow for efficient production of various biscuit types, helping these enterprises expand their product lines and increase market share.

Video of Industrial Biscuit Production Line

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online