Industrial Pork Rind Frying Machine with Oil Filtering

Output:300-1000KG/H

Output:300-1000KG/H Voltage:380V

Voltage:380V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

The pork rind frying machine is usually developed for large scale pork rinds snack production. By integrating automatic oil filtering and temperature control, this frying machine supports continuous production with reduced oil consumption and improved product quality.

To adapt to different production environments, the machine supports electric heating, gas heating, and steam heating. Designed for high-temperature, long-duration frying, the fryer machine boasts high-quality construction and a long service life.

Application of Pork Rind Frying Machine

The machine is mainly used for frying pork rinds products, including pork skin, pork cracklings, and other snacks. During frying, pork skin requires precise temperature control to achieve proper expansion, crisp texture, and uniform color without burning or excessive oil absorption.

This industrial frying system is suitable for:

- Pork rinds

- Pig skin snacks

- Pork cracklings

- Expanded meat-based snacks

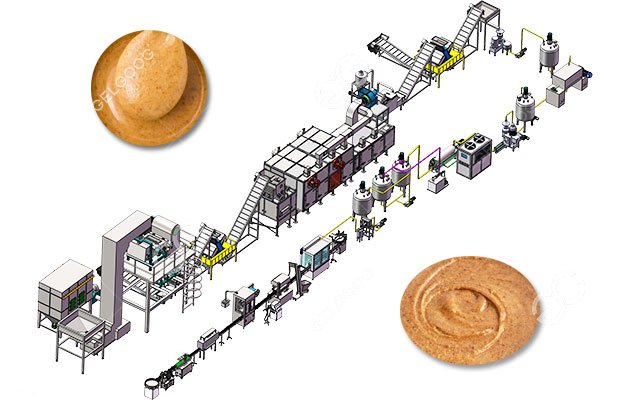

The frying machine can be integrated into a complete pork rind production line, working together with cutting, drying, seasoning, and packaging equipment.

Structure and Working Principle of Industrial Pork Rind Fryer

The frying machine typically adopts a continuous belt-type frying structure, allowing pork skin pieces to move steadily through the frying oil.

- Main components include:

- Frying tank with heat insulation

- Stainless steel mesh belt or dual-belt conveying system

- Automatic oil heating and temperature control system

- Integrated oil filtering unit

- Lifting or circulation system for residue removal

Pork rinds are evenly conveyed through the oil bath at a controlled speed. Frying temperature and time can be adjusted according to product thickness and expansion requirements, ensuring consistent frying results.

Integrated Oil Filtering System

One of the key features of an industrial pork rind frying machine is the automatic oil filtering system. During pork skin frying, residues and fine particles are continuously generated, which can degrade oil quality if not removed.

The built-in oil filtering system:

- Continuously removes crumbs and impurities

- Extends frying oil service life

- Maintains stable oil color and flavor

- Reduces oil replacement frequency

This system significantly lowers operating costs while improving food safety and product consistency.

Key Advantages of Pork Rind Frying Machine

- Continuous and Stable Operation: The continuous frying design supports long working hours and high production capacity, making it suitable for industrial snack food factories.

- Precise Temperature Control: Accurate oil temperature control ensures uniform expansion and crisp texture, preventing under-frying or burning of pork rinds.

- Reduced Oil Consumption: The oil filtering system keeps oil clean, reduces waste, and improves frying efficiency.

- Hygienic and Durable Design: The industrial pork rind fryer is made of food-grade stainless steel, ensuring corrosion resistance, easy cleaning, and compliance with food processing standards.

- Flexible Capacity Configuration: Production capacity can be customized according to factory requirements, from medium to high-output pork rind production.

How to Fry Crispy Pork Rinds

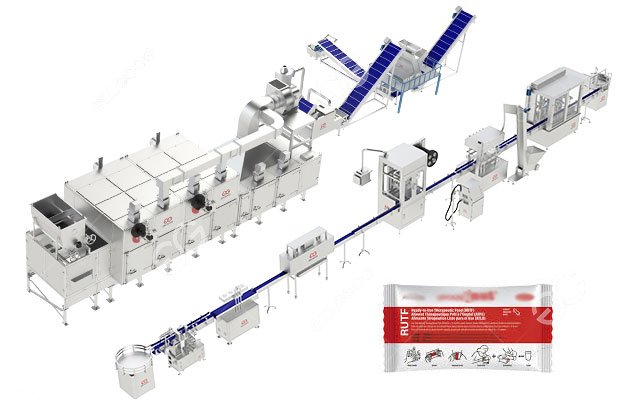

The continuous pork rind fryer machine can be connected with:

- De-oiling and cooling conveyors

- Seasoning machines

- Automatic packaging machines

Why Choose an Industrial Pork Rind Frying Machine?

- Higher production efficiency

- Lower labor dependency

- More consistent product quality

- Better oil management

- Long-term cost savings

For manufacturers focused on pork rind and pig skin snack production, this fryer machine provides a reliable and scalable frying solution.

Technical Data

| Model | Heating Method | Power(KW) | Size(mm) | Capacity |

| GGLZE2000 | Electric | 54 | 2200*785*1350 | 200kg/h |

| GGLZE3500 | Electric | 90 | 3700*1600*2200 | 300kg/h |

| GGLZE5000 | Electric | 144-171 | 5200*1600*2200 | 400kg/h |

| GGLZE6500 | Electric | 190 | 6700*1600*2200 | 600kg/h |

| GGLZE8000 | Electric | 234-252 | 8200*1600*2200 | 800kg/h |

| GGLZG2000 | Gas | 10W C | 2200*800*1400 | 200kg/h |

| GGLZG3500 | Gas | 20W C | 3700*1900*2400 | 400kg/h |

| GGLZG5000 | Gas | 30W C | 5200*1900*2400 | 600kg/h |

| GGLZG6500 | Gas | 40W C | 6700*1900*2400 | 750kg/h |

| GGLZG8000 | Gas | 50W C | 8200*1900*2400 | 950kg/h |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online