RUTF Production Line for Nutritious Food Manufacturing

Output:

Output: Voltage:

Voltage: Power:

Power:  Payment Method:

Payment Method:

Features

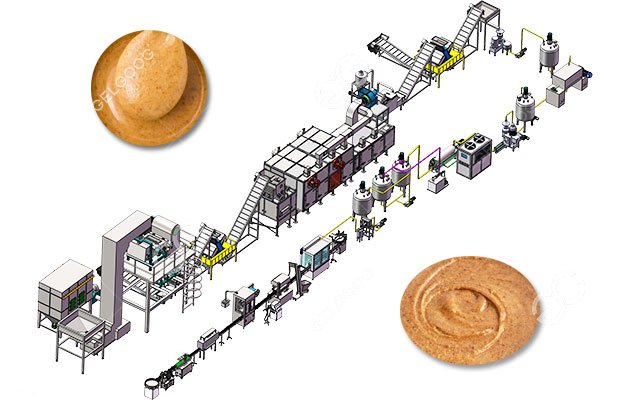

The RUTF production line produces high-energy, nutrient-rich therapeutic food. Using peanut butter as the core ingredient, it produces high-quality RUTF products through multiple processes including roasting, grinding, mixing, homogenization, and cooling.

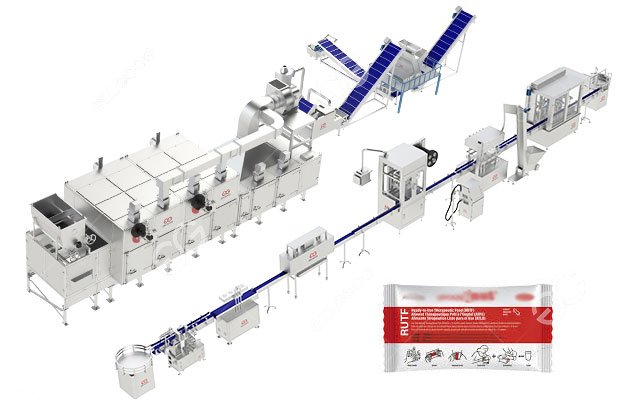

The entire production line is highly automated and suitable for large-scale production needs. This effectively meets the procurement requirements of food processing companies, nutritional food manufacturers, and international aid organizations.

Automatic RUTF Production Line Features

- The entire process is automated, including peanut grinding, mixing and homogenization, vacuum mixing, and quantitative packaging. This ensures stable and continuous production of RUTF peanut paste.

- Low-temperature vacuum technology and precise mixing techniques are employed to ensure even distribution of peanuts, vitamins, and minerals. This maximizes the retention of key nutrients required for RUTF product.

- High-shear homogenization equipment results in a more uniform and smooth texture for the RUTF peanut paste. It can be easily compressed or extruded into small packages.

- The production line uses stainless steel materials and enclosed processing, complying with GMP, HACCP, and ISO22000 standards. This ensures that the RUTF production process remains free from contamination.

- Optimized process design reduces energy consumption and improves RUTF production efficiency. It also guarantees long-term stable operation of the equipment, making it suitable for large-scale nutritional food production and emergency relief projects.

The RUTF processing line can be customized according to different RUTF formulations (peanut paste, high-protein, added vitamins and minerals, etc.) and packaging specifications. It supports multi-flavor, multi-batch continuous production.

RUTF Market and Applications

- Medical and Nutritional Intervention: Used to address child malnutrition, widely applied in developing countries in Africa and Asia, as well as in international aid programs.

- Charitable Assistance and Humanitarian Relief: RUTF peanut butter are easy to store and transport, facilitating emergency nutritional assistance.

- Health and Nutrition Food Industry: High-energy, high-protein RUTF can be expanded into the healthy snack and high-energy food market.

- OEM/ODM Customization: Suitable for food companies to customize branded RUTF products, enabling multi-variety and multi-flavor production.

With the growing global demand for child nutrition and emergency relief food, the RUTF market has long-term development potential. Adopting efficient and stable RUTF processing line ensures manufacturers maintain a competitive advantage in the international market.

GELGOOG Provide the RUTF Solutions

1.Complete Turnkey Solutions

From raw material pretreatment to automatic packaging, we provide complete turnkey solutions for the entire process, reducing installation and commissioning time.

2.Customized Production Solutions

Based on customer capacity, formulas, product specifications, and packaging requirements, we provide exclusive design solutions to meet different production scales and market demands.

3.Technical Support and Training

We provide operational training, production process guidance, maintenance manuals, and remote technical support to ensure that customers quickly master the production process and guarantee the long-term stable operation of the RUTF production line.

4.After-Sales Service and Maintenance

We establish a long-term after-sales service system, including regular maintenance, spare parts supply, and troubleshooting, to reduce customer production risks and improve production efficiency.

Technical Data

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online