Pork Skin Cracklings Frying Machine High Efficiency

Output:300-1000KG/H

Output:300-1000KG/H Voltage:380V

Voltage:380V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

The pork skin frying machine is an industrial frying solution, it can make fried pork skin, pork cracklings. This equipment has high production capacity and good performance, and can process 300-1000 kilograms of pork skin per hour.

This fryer machine uses a continuous frying process, making it more efficient. It results in more consistent product quality and more uniform expansion, making it ideal for commercial snack food manufacturers.

Working Process of Pork Skin Frying Machine

Pork skin is fed into the fryer machine through a continuous conveyor system. The product is fully immersed in hot oil and conveyed at a controlled speed to ensure uniform frying time.

An automatic temperature control system maintains stable oil temperature, which is critical for proper expansion of pork skin. After frying, the finished product is discharged continuously, enabling uninterrupted production.

Features of Pork Cracklings Frying Machine

- Continuous Frying System: Ensures uninterrupted production and consistent frying quality, eliminating batch differences common in traditional fryers.

- Precise Temperature Control: Automatic temperature control maintains stable oil temperature, ensuring uniform expansion and crispiness of pork skin and cracklings snacks.

- Food-Grade Stainless Steel: This pork skin fryer machine is manufactured from food-grade stainless steel for hygiene, corrosion resistance, and easy cleaning.

- Conveyor Belt Structure: The conveyor system provides consistent residence time for each piece of pork skin, preventing uneven frying.

- Oil Circulation & Filtration: This fryer equipped with an oil circulation system and optional filtration unit to reduce oil impurities, extend oil life, and improve product quality.

Why Choose This Pork Skin Frying Machine

- Consistent Product Quality: Helps producers achieve uniform expansion and stable texture of pork skin snacks, reducing quality variation in daily production.

- Predictable Output Planning: This frying machine supports continuous production schedules, making it easier to plan capacity, labor, and delivery timelines.

- Reduced Product Loss: Improves process stability during frying, helping minimize under-fried or over-fried pork skin.

- Lower Long-Term Operating Cost: Designed for stable long-hour operation, helping control oil usage, labor input, and maintenance frequency.

- Suitable for Commercial Growth: Meets the needs of manufacturers scaling pork skin production from pilot level to commercial volumes.

- Proven Application in Pork Skin Snacks: Widely applied in pork rind and crackling snack processing, matching real market production requirements.

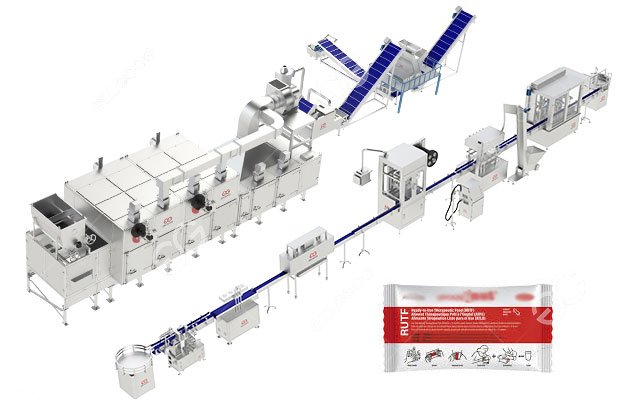

This pork cracklings frying machine is typically used in conjunction with an oil deoiling machine, seasoning machine, and packaging machine to form a small production line. It focuses on automating the production of pork skin snacks.

Technical Data

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online