Automatic Sesame Tahini Processing Line Manufacturer

Output:500KG/H

Output:500KG/H Voltage:380V

Voltage:380V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

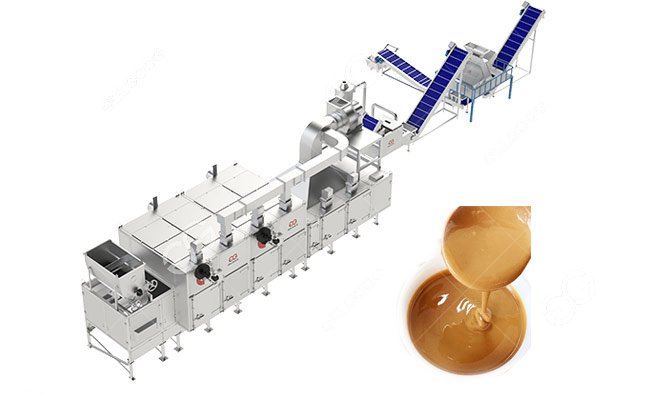

This sesame tahini processing line operates stably and is specifically designed to produce sesame paste with a uniform texture. It was developed specifically to meet the market's increasing demand for efficient and hygienic sesame paste production.

The line is composed of several coordinated units, including sesame washing and drying equipment, lifting conveyor, continuous roasting machine, storage and feeding system, sesame grinding machine, mixing tank, vacuum degassing unit, transfer pump, packaging equipment, and other auxiliary components.

Applicable Sesame Tahini Processing Line

This production line is ideal for processing plain and multi-flavored sesame paste. Designed for large-scale, standardized production, it averages 100-2000 kg/h.

The entire line utilizes an automated control system, operating continuously from raw material cleaning, roasting, grinding to finished product bottling. Suitable for factory production environments, it can sustainably and stably output high-quality sesame paste, meeting the flavor and capacity demands of different markets.

Working Video of Automatic Sesame Tahini Line

Features of Automatic Tahini Processing Line

➊ All parts in contact with materials are made of food-grade materials, which are corrosion-resistant and easy to clean. This not only makes the product more hygienic and safer but also extends the equipment's lifespan.

➋ This production line employs a highly integrated design, achieving fully automated operation from raw material processing to finished sesame paste. This streamlined workflow significantly improves efficiency and minimizes human intervention.

➌ Electric or gas heating can be flexibly configured according to the customer's factory conditions. Rapid heating, high thermal efficiency, and uniform roasting effectively preserve the sesame aroma.

➍ The sesame tahini processing line has a compact structure, a neat and attractive appearance, and is easy to operate and maintain. It occupies a small area, and the user-friendly control system facilitates daily maintenance and production management.

➎ A multi-stage grinding system ensures a smooth texture and pure flavor in the sesame paste, meeting the quality requirements of the high-end market.

➏ Professional manufacturers provide technical support and customization services. Different capacity and configuration schemes can be designed according to customer needs, helping to build an efficient and intelligent sesame paste production line.

Advantages of Sesame Tahini Processing Line

1. Advanced technology and stable performance: This line enhances labor productivity and product consistency while reducing overall production costs.

2. Attractive design and compact structure: The equipment runs smoothly with low noise, reliable operation, and a long service life.

3. Made of food-grade stainless steel: All key components of automatic sesame tahini line are durable, corrosion-resistant, and meet food hygiene standards.

4. Flexible capacity options: Different production capacities are available to meet various customer needs. The system is energy-efficient, safe, and environmentally friendly.

5. Easy operation and maintenance: Designed for user convenience, with electrical systems that comply with national safety standards, ensuring reliable and secure performance.

Technical Data

| Item | Name | Dimension(mm) | Power(KW) | Weight (KG) |

| 1 | Screw Elevator | 2000*600*2000 | 0.75 | 150 |

| 2 | Continuous Cleaning Machine | 2300*500*1350 | 0.75 | 200 |

| 3 | Drying Machine | 1000*800*650 | 1.5 | 100 |

| 4 | Elevator | 3000*600*3000 | 0.75 | 220 |

| 5 | Continuous Roasting Machine | 3500*1400*2600 | 75(Electric Model) | 3000 |

| 6 | Pneumatic Conveyor | 1.5 | 250 | |

| 7 | Cooling Storage Hopper | 1500*1000*2000 | 1.5 | 250 |

| 8 | Combined Grinding Machine | Single 1000*400*900 | 22 | Single Machine 270 |

| 9 | Storaging Tank | 300L | 150 | |

| 10 | Mixing Tank | 300L | 2.2 | 300 |

| 11 | Vacuum Degassing Tank | 300L | 2.2 | 300 |

| 12 | Paste Pump | 1.5x2 | 100*2 sets |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online