Gelgoog Almond Butter Manufacturing Line Manufacturer

Output:100-2000kg/h

Output:100-2000kg/h Voltage:380V

Voltage:380V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

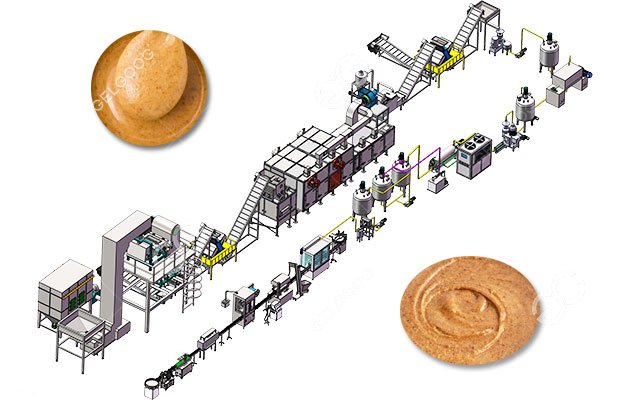

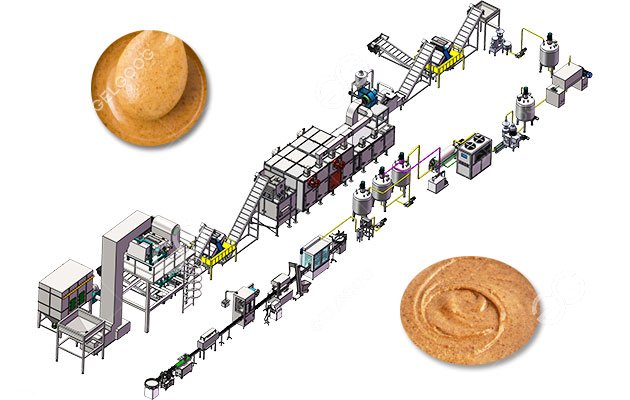

The almond butter manufacturing line is an automated processing system used for the industrial production of almond butter, and related nut butter products. It is a high quality equipment developed and manufactured by Gelgoog.

This production line involves peeling the almonds, followed by roasting, grinding, mixing, and final product almond butter packing. It is suitable for food processing plants, nut processing companies, and functional food production projects.

Features of Almond Butter Manufacturing Line

- High Production Capacity: Production capacity ranges from 100 to 2000 kg/h. Supports continuous operation in small, medium, and large-scale factories, increasing output per unit of time.

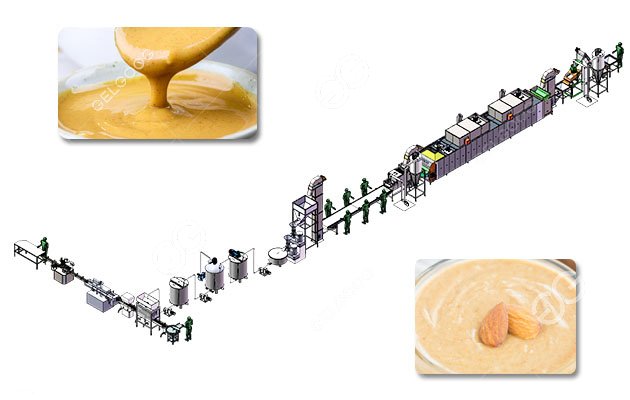

- Stable Grinding Fineness: The production line adopts a multi-stage grinding structure. The fineness of the almond butter can be controlled between 80 and 120 mesh, with uniform particle distribution.

- All Food Grade Materials: Key contact parts are made of SUS304 or SUS316 stainless steel. The almond butter manufacturing machine meets food safety standards, is corrosion-resistant, and easy to clean.

- High Degree of Automation: The core equipment can achieve continuous feeding and stable output, reducing manual labor intensity. Suitable for long-term operation of large-scale almond butter lines.

- Low Energy Consumption and Maintenance Costs: The machine structure is reasonably designed with high transmission efficiency. While ensuring production capacity, it effectively controls energy consumption, has a long maintenance cycle, and controllable operating costs.

Main Equipment Components of Almond Butter Manufacturing Machine

- Almond Peeling Machine: Utilizes a wet process combining hot water soaking and mechanical peeling for efficient almond peeling.

- Almond Roasting and Cooling Line: Evenly roasts almonds followed by rapid cooling to preserve flavor and maintain kernel integrity.

- Almond Grinding Machine: Continuously grinds almonds into a fine almond butter with uniform fineness, meeting the process requirements of different almond butter products.

- Mixing and Refining Equipment: Improves the consistency of the almond butter and prevents oil-water separation.

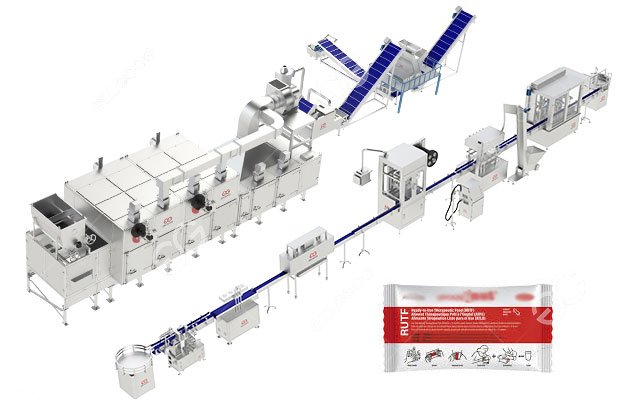

- Almond Butter Filling Machine: Automatically fills almond butter quickly and accurately, suitable for continuous production.

Advantages of Gelgoog Almond Butter Manufacturing Line Manufacturer

- Extensive R&D Experience: Gelgoog has focused on nut and food processing equipment for many years, providing customized almond butter solutions based on customer needs.

- High Quality: Key contact parts are made of food-grade stainless steel. The scientific design ensures stable equipment operation.

- Complete Process Solutions: We provide a complete almond butter production line from raw material pretreatment, grinding, mixing, refining to filling –a one-stop solution.

- Flexible Customization Capabilities: Gelgoog can flexibly adjust the production line configuration according to production requirements, factory layout, and product characteristics to meet different scales and product needs.

- Global Service and Support: Our equipment has been exported to many countries and regions. We provide installation and commissioning, training, and after-sales maintenance services to ensure long-term stable production for our customers.

Technical Data

| Item | Name | Dimension(mm) | Power(KW) | Weight (KG) |

| 1 | Screw Elevator | 2000*600*2000 | 0.75 | 150 |

| 2 | Continuous Cleaning Machine | 2300*500*1350 | 0.75 | 200 |

| 3 | Drying Machine | 1000*800*650 | 1.5 | 100 |

| 4 | Elevator | 3000*600*3000 | 0.75 | 220 |

| 5 | Continuous Roasting Machine | 3500*1400*2600 | 75(Electric Model) | 3000 |

| 6 | Pneumatic Conveyor | 1.5 | 250 | |

| 7 | Cooling Storage Hopper | 1500*1000*2000 | 1.5 | 250 |

| 8 | Combined Grinding Machine | Single 1000*400*900 | 22 | Single Machine 270 |

| 9 | Storaging Tank | 300L | 150 | |

| 10 | Mixing Tank | 300L | 2.2 | 300 |

| 11 | Vacuum Degassing Tank | 300L | 2.2 | 300 |

| 12 | Paste Pump | 1.5x2 | 100*2 sets |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online