Automatic Granada Pomegranate Sorting Line 1t/h

Output:1t/h

Output:1t/h Voltage:380V

Voltage:380V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

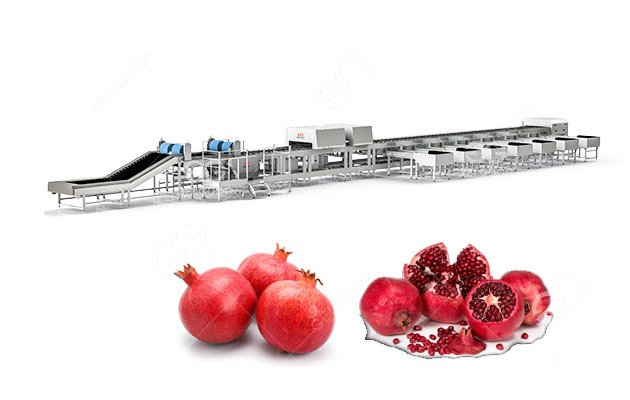

The pomegranate sorting line is a professional automated sorting system. It is suitable for freshly harvested fruits such as pomegranates, oranges, kiwis, pineapples, apples, citrus fruits, pears, tomatoes, etc.

The whole sorting line integrates conveying, washing (optional), inspection, and grading. It can stably and efficiently complete standardized sorting of pomegranates by weight, size, or color, helping fruit processing enterprises improve efficiency and market competitiveness.

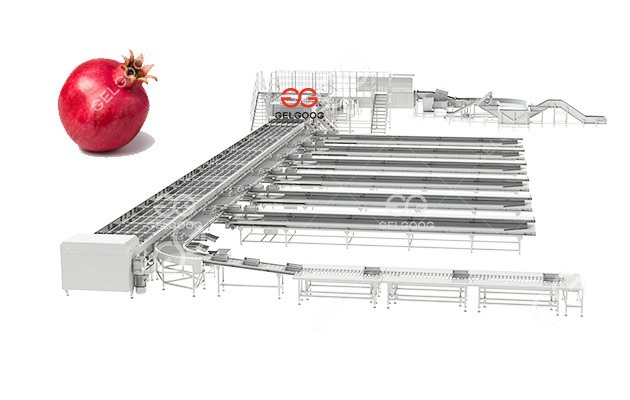

Structure of the Automatic Pomegranate Sorting Line

This line adopts a modular design, mainly composed of a feeding conveyor system, an automatic grading machine, a finished product confluence conveyor system, and an electrical control system.

Key contact components are made of food-grade materials in compliance with hygiene standards for fruit and vegetable processing. With a flexible and modular design, the sorting line can be adapted to different site layouts, capacity demands, and grading needs, suitable for fruit processing and export packing facilities.

Different Grading Methods in Granada Sorting Line

★ Weight and Size Grading

Weight and size grading is currently the most widely used pomegranates sorting method. It is a mature, low-cost, and highly stable method. Using roller gaps or individual pomegranates weighing, pomegranates are quickly sorted, making it particularly suitable for spherical or batch-processed pomegranates. It is a fundamental component of most pomegranates initial processing and grading/packaging stages.

★ Appearance and Color Grading

Appearance grading, based on machine vision and automation technology, objectively and accurately identifies the color, shape, and surface defects of pomegranates. Through multi-angle imaging and intelligent algorithm analysis, it achieves high-efficiency and highly consistent quality grading, significantly reducing reliance on manual labor. It is a core method in modern industrial fruit processing.

★ Internal Quality Grading

Internal quality grading uses non-destructive testing technology to identify and grade the sugar content, acidity, and potential defects inside the pomegranates and other fruits, ensuring edible quality and consistency without damaging the pomegranate fruit. This technology represents a high-end direction in post-harvest pomegranate fruit processing and is crucial equipment supporting branding and high-value-added markets.

Features of Pomegranate Sorting Line

- High Grading Accuracy: Employs weighing or roller grading methods to ensure stable grading and minimal error for each pomegranate.

- Strong Expandability: The automatic pomegranate sorting machine can be connected to downstream equipment such as washing, waxing, and packaging systems.

- Good Fruit Protection: The pomegranate conveying and grading process is smooth, reducing collisions and compression, and lowering pomegranates fruit loss rates.

- High Operating Efficiency: The granada sorting line features continuous automatic operation, suitable for large-scale, long-term stable production.

- Easy Operation: Parameters can be flexibly set in the control system, allowing for quick size switching and convenient maintenance.

Applications of Automatic Pomegranate Sorting Machine

This grading machine is not only suitable for Granada pomegranates, but can also be adjusted according to needs for grading round or near-round fruits such as citrus, apples, and pears. It is widely used in orchard cooperatives, fruit processing plants, cold chain sorting centers, and export-oriented fruit enterprises.

Technical Data

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online