Automatic Chocolate Cone Filling Machine Price

Output:2400 L/H

Output:2400 L/H Voltage:380v-50hz

Voltage:380v-50hz  Power: /

Power: / Payment Method: Payment Method: T/T, L/C, Western Union

Payment Method: Payment Method: T/T, L/C, Western Union

Features

The automatic chocolate cone filling machine is an advanced food processing equipment designed for filling ice cream cones, waffle cones, and other edible containers with chocolate, caramel, or other liquid fillings.

It ensures high precision, speed, and hygiene, making it ideal for:

✔ Ice cream & dessert manufacturers

✔ Large-scale bakeries & confectionery businesses

✔ Food processing plants

Features of Automatic Chocolate Cone Filling Machine

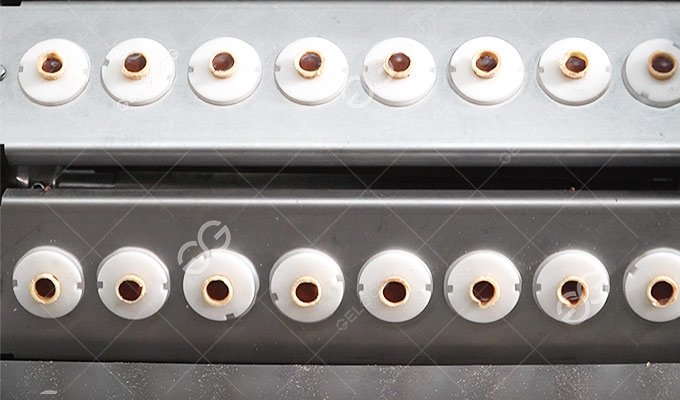

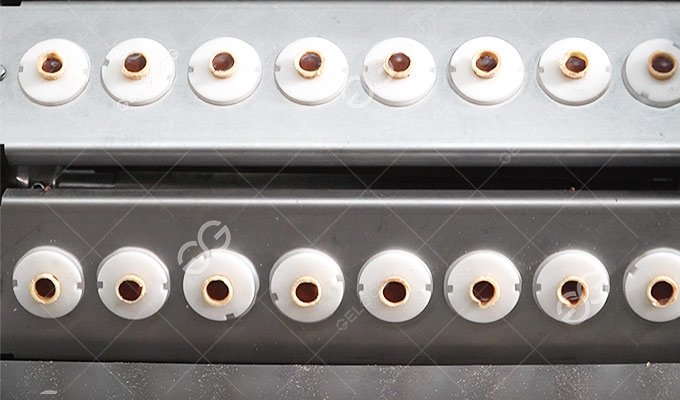

✅ High-speed filling – The machine can fill 8-12 cones each time (adjustable depending on the model).

✅ Precision nozzle – Ensures accurate filling amount every time (5-50 ml per chocolate cone, adjustable range).

✅ This chocolate cone filler machine built from food-grade 304 stainless steel, the unit wipes down in seconds and passes every hygiene checkpoint.

✅ Touch screen control panel – Easily adjust filling amount, speed and time.

✅ Touch screen control panel – Easily adjust filling amount, speed and time.

✅ Multi-layer filling option – Supports dual flavor filling (e.g. chocolate + chopped nuts).

✅ Low maintenance – The filling machine's structure is sturdy and durable, with minimal downtime.

How Does It Work? (Operation Steps)

- Preparation – Place the prepared cone into the hole of the filling machine.

- Filling setting – Pour the melted chocolate into the machine's reservoir and set the desired volume.

- Automatic filling – The machine accurately dispenses the chocolate into each cone.

- Cooling and packaging – The filled cones are sent to a cooling conveyor before packaging. Finally, the packaging is weighed.

The automatic chocolate cone filling machine price depends on several key factors: production capacity, automation level, material quality, brand reputation. And additional features, such as multiple flavor filling function, touch screen control or custom nozzle design.

High-speed, highly automated and durable machines are naturally more expensive, while small semi-automatic models provide a more affordable option for start-ups. Import duties, shipping costs and after-sales service packages will also affect the final price.

Recommended Supporting Equipment

To maximize production efficiency, consider pairing your chocolate cone filler machine with these complementary systems:

- Cone Baking Machine – Produces fresh, uniform cones for filling.

- Chocolate Melting Tank – Maintains optimal viscosity for smooth dispensing.

- Cooling Tunnel – Rapidly sets filled cones for packaging.

- Automatic Packaging Machine – Pack, seals and labels finished products.

- Conveyor Belt System – Streamlines workflow between stations.

Our automatic chocolate cone filling machines have been successfully exported to many countries, including the Peru, Indonesia, Australia, Argentina, Philippines, Bolivia and other countries.

Trusted by leading ice cream brands, confectionery manufacturers, and food processing plants, our machines consistently deliver high performance, reliability, and efficiency—earning widespread acclaim for their precision engineering and durable design.

Technical Data

| Capacity | 2400 L/H |

| Voltage | 380v-50hz |

| Gas consumption | 1.9m³/min |

| Weight | 2000kg |

| Size | 4800*1140*2000mm |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online