Automatic Roasted Peanut Production Line GELGOOG

Output:200-1000 KG/H

Output:200-1000 KG/H Voltage:380V

Voltage:380V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

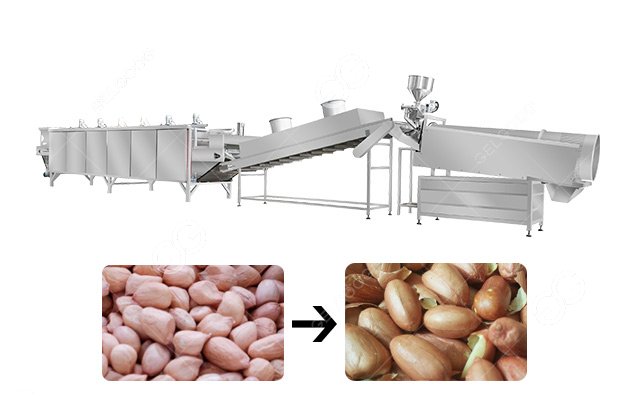

The roasted peanut production line includes roasting, cooling, peeling (optional), seasoning, and packaging. It is designed for large-scale, efficient production of high-quality roasted peanuts.

This production line performs most of the work independently. Precise temperature and time control ensure not only higher quality roasted peanuts but also consistent taste and texture from batch to batch.

Features of Roasted Peanut Production Line

- The entire line is PLC-controlled. From peanut loading to finished product packaging, continuous and automated operations are achieved.

- The roasting process utilizes an intelligent temperature control system, ensuring uniform heating and minimal temperature fluctuations. The roasting temperature and time can be customized based on the peanut variety and target taste.

- Automatic peanut roasting line utilizes high-efficiency insulation materials and hot air circulation technology, effectively reducing energy consumption and operating costs.

- The modular design allows for flexible selection of modules such as roasters, seasoning machines, and packaging machines based on customer needs.

- Equipment's main body is constructed of 304 or higher grade stainless steel. The contact surface is smooth without dead corners and is easy to clean and maintain.

Roasted Peanut Processing Process

- Roasting and Cooling: This is a core process in the roasted peanut production line. It automatically and evenly roasts peanuts. After roasting, the system automatically switches to strong air cooling for rapid cooling and setting.

- Peeling (optional): For peeled roasted peanuts, the cooled peanuts enter a peeling machine where the red skin is removed through gentle friction or other methods.

- Seasoning (optional): Roasted peanuts are sprayed with cooking oil, salt, spices, and other seasonings and evenly tumbled to ensure they adhere to the peanuts, creating a variety of flavors.

- Packaging: The final product is weighed and packaged by an automatic packaging machine. Nitrogen-filled or vacuum-packed packaging can be selected to extend shelf life, or directly packaged in cans or bags.

Applications of Automatic Roasted Peanut Production Line

- Snack food industry: Large-scale production of bagged roasted peanuts for snacks.

- Food processing and catering industry: Providing roasted, blanched peanuts or ground peanuts as raw materials for restaurants, bakeries, chocolate factories, and confectionery factories.

- Seasoning industry: Pre-processing raw materials (roasting and blanching) for peanut butter production.

- Export trade: Producing high-quality roasted peanuts that meet international standards for export.

Main Related Equipment Components

- Roasting and Cooling Machine: This is a main machine in this peanut roasting line. Combines roasting and cooling functions in one machine. Automated operation saves space and manpower.

- Peeling Machine: Removes the red skin from peanuts.

- Seasoning Machine: Adds flavor to peanuts.

- Metal Detector: Detects and removes potential metal impurities to ensure safety.

- Automatic packaging machine: Performs packaging operations such as metering, filling, and sealing.

Technical Data

| No. | Name | Power(kw) | Dimension(mm) |

| 1 | Lifting Machine | 0.75 | Height:2000 |

| 2 | Roasting and Cooling Machine |

4.4 Gas Consumption: 10-12KG/H |

8500*2250*2600 |

| 3 | Seasoning Machine | 0.75 | 1400*900*1600 |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online