500KG/H Plumpy Nut Production Equipment for RUTF

Output:300-2000kg/h

Output:300-2000kg/h Voltage:380v

Voltage:380v Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

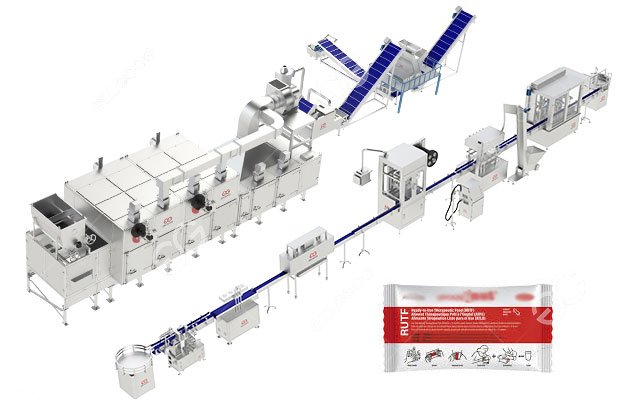

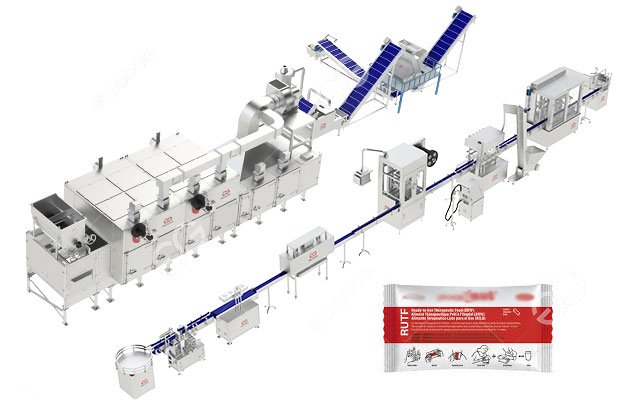

The Plumpy Nut production equipment is a complete industrial production line specifically designed for the production of ready-to-eat therapeutic foods (RUTF), particularly for the large-scale production needs of high-energy nutritional supplements like Plumpy Nut.

The entire line is fully automated, from raw material processing to final packaging, with a stable hourly capacity of 500 kg, meeting the production needs of medium to large-sized nutritional food manufacturers and humanitarian aid organizations.

Features of Plumpy Nut Production Equipment

- Fully Automated Control: Utilizing a PLC and touchscreen for centralized control, enabling one-button operation and parameter adjustment. This reduces manual labor intensity and production errors. Intelligent monitoring displays real-time status and records data, ensuring full traceability.

- Energy-Efficient Design: The production line uses a heat recovery system and high-efficiency motors, saving approximately 15-20% more energy than traditional equipment. Optimized production processes reduce raw material loss and improve overall energy utilization.

- Hygienic Design Standards: All food-contact parts are made of 304 stainless steel, meeting food-grade hygiene requirements. The Plumpy Nut production line structure avoids dead corners and uses quick-connect connections for easy cleaning and maintenance, preventing cross-contamination.

- Precise Nutritional Ratio: Equipped with high-precision metering devices and an automatic dispensing system, the machine ensures that raw materials such as peanut butter, milk powder, sugar, and vitamin and mineral complex are precisely mixed in scientific proportions, with an error rate of less than 0.5%, guaranteeing nutritional consistency in each batch.

- Flexible Adaptability: The modular design allows for adjustments to certain processes based on specific customer needs, adapting to changes in Plumpy Nut product formulas and packaging specifications. The RUTF production line is equipped with upgrade interfaces for future capacity expansion or functional additions.

Five Core Features of Plumpy Nut Production Equipment

1. Raw Material Pretreatment System: This is the initial step of the RUTF production line, specifically designed for processing the core raw material, peanuts.

- Peanut Roasting Machine: Employs a hot air circulation system to precisely control temperature and time, uniformly roasting peanuts to the ideal doneness, enhancing flavor and deactivating anti-nutritional factors.

- Peanut Peeling Machine: Efficiently removes the red skin from roasted peanuts, using soft friction technology to maximize the integrity of the peanut kernels.

- Grinding Machine: Grinds peeled peanut kernels into a smooth and fine peanut butter, with a particle size controllable below 20 microns, ensuring a smooth and grain-free product texture.

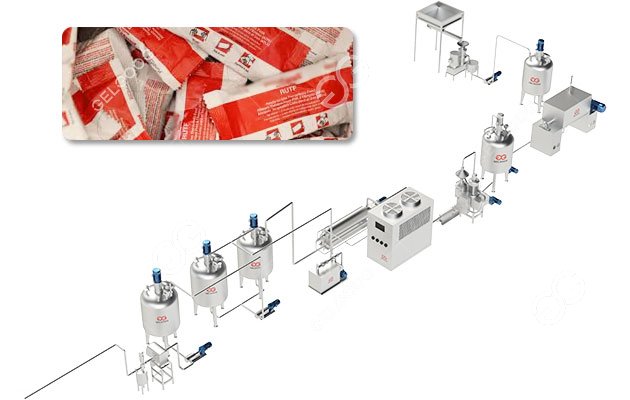

2. Ingredient and Main Mixing System: This system completes the precise metering and initial mixing of all basic raw materials.

- Automatic Batching Unit: This system integrates multiple ingredient silos for components such as milk powder, sugar, and vitamin premixes, coupled with a precision dosing mechanism ensuring formulation accuracy within ±0.1%.

- High-Shear Primary Mixer: Designed with a specialized rotor-stator assembly, this mixer applies intense shear forces to rapidly blend viscous peanut paste, oils, and powdered ingredients into a homogeneous semi-fluid base in just 3–5 minutes. The process naturally elevates material temperature to 40–50°C, facilitating viscosity reduction and enhancing blending effectiveness.

3. Fine mixing homogenization and temperature control system: This is a crucial step in the Plumpy Nut production equipment line, ensuring long-term Plumpy Nut product stability and is fundamentally different from the main mixing system.

- Jacketed fine mixing homogenizer: Equipped with a precise temperature control jacket and a low-speed scraping and stirring device. After receiving material from the main mixer:

- Precision Temperature Control: The material is slowly cooled from 50°C to the ideal filling temperature of 32°C ± 2°C at a controllable rate (typically 1-2°C/min) using cooling water circulating within the jacket.

- Deep Homogenization: Microscopic inhomogeneities are eliminated during slow mixing (20-40 rpm) for up to 30-60 minutes, ensuring uniform distribution of vitamins and minerals.

- Structural Maturation: Oils and solid particles are fully combined to form a stable network structure, preventing separation of the oil and paste during shelf life.

4. Filling and Packaging System: The final processed RUTF paste is packaged.

- Piston-Type Quantitative Filling Machine: Designed specifically for high-viscosity materials, it uses a servo-controlled piston cylinder, achieving a filling accuracy of ±1 gram. A nitrogen filling system is optional to extend shelf life.

- Automatic Bag Packaging Machine: Fully automatic, it completes bag picking, opening, filling, vacuuming (or nitrogen filling), heat sealing, and cutting. The packaging speed is adjustable to accommodate different bag sizes.

5. Quality Inspection System

- Pipeline Metal Detector: Installed in the material pipeline before filling, it detects and removes material flow containing metal foreign objects online, with sensitivity up to Fe 0.8mm and Sus 1.2mm.

- Dynamic Checkweigher: Each finished RUTF Plumpy Nut packet undergoes 100% weight verification with an accuracy of ±0.5g. The system automatically rejects any out-of-specification product while simultaneously generating real-time statistical data on production metrics.

Technical Support - Plumpy Nut Production Line

- Installation and Commissioning: Engineers provide on-site guidance for equipment installation and commissioning, and train operators to operate independently.

- Warranty and Maintenance: The entire machine comes with a 12-24 month warranty, with longer warranties for critical components. Regular maintenance plans and spare parts support are provided to reduce downtime risks.

- Technical Training: Systematic training is provided on Plumpy Nut production equipment operation, daily maintenance, troubleshooting, and process optimization.

- Spare Parts Supply: Adequate inventory of commonly used spare parts is maintained for rapid supply in emergencies. Replacement guidance is provided.

- Process Support: Assistance is provided in optimizing production processes, adapting formula adjustments, and resolving technical problems encountered in production.

- Remote Support: Remote monitoring and fault diagnosis are achieved through IoT technology, enabling rapid response and providing solutions.

Technical Data

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online