300KG/H Ghana Chips Frying Machine for Chin Chin Snacks

Output:300KG/H

Output:300KG/H Voltage:380V

Voltage:380V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

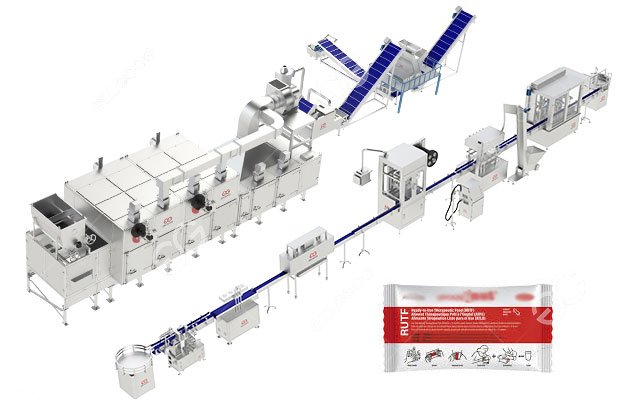

The ghana chips frying machine is a high efficiency continuous frying equipment. It is specifically designed for the industrial production of traditional crispy snacks such as ghana chips, chin chin, etc.

This machine can achieve a stable output of 300 kg/hour. In addition, many other models are available to meet different production needs. It is ideal for small and medium-sized food processing enterprises as well as large snack companies.

Features of Ghana Chips Frying Machine

- High-Efficiency Heat Circulation System: The system employs a unique three-dimensional heat exchange structure, boosting thermal efficiency by 30%. Oil temperature control accuracy reaches ±2°C, ensuring uniform color and crispy texture in every batch.

- Stepped Variable Frequency Conveyor Design: The ghana chips fryer machine’s three-layer variable frequency conveyor belt, acting as the actuator, can be flexibly programmed to automatically manage the entire process of frying intensity, penetration, and final shaping. This standardizes complex processes, frees up manpower, and eliminates human error.

- Dual-Effect Oil Filtration & Antioxidant System: Centrifugal filtration and nitrogen protection work in synergy, extending oil life by over 40%. This integrated approach reduces costs and safeguards food safety in one stroke.

- Food-Grade Stainless Steel Body: Constructed entirely of 304 stainless steel, meeting food hygiene standards. This chin chin fryer machine equipped with a touchscreen for centralized control, real-time monitoring of key data such as oil consumption, output, and temperature.

- Modular Temperature Zone Control: Five independent heating zones support different recipe and process requirements. One-button switching of production modes adapts to various traditional snack frying parameters.

Operating Process for Ghana Chips Fryer Machine

- Preheating Preparation: Start the equipment and set the frying temperature (usually 160°C-190°C).

- Raw Material Placement: Evenly place the shaped frying machine onto the feeding conveyor belt (elevator).

- Automatic Frying: The ghana chips and chin chin are gradually fried via the conveyor belt; the total time is adjustable from 3 to 5 minutes.

- Oil Filtering and Cooling: After frying, the ghana chips enter a vibrating oil filter and are then conveyed to the cooling line.

- Collection and Packaging: After cooling, the ghana chip are automatically sent to the collection port for subsequent seasoning or packaging.

- Cleaning and Maintenance: After production, a self-cleaning program is activated to clean the filter screen regularly.

Optional Industrial Chin Chin Fryer Machine Specifications

- Compact: 100-300kg/h

- High-capacity: 400-500kg/h

- Large-capacity: Over 600kg/h

- Customized: Adjustable temperature zones and conveyor belt material according to customer recipes

- Suitable Energy Sources: Natural gas, electric heating, steam, etc.

Applications of the Ghana Chips Frying Machine

This machine is not only specialized in producing African snacks ghana chips, chin chin snacks, but also suitable for various snacks requiring even frying, such as traditional fried dough, fried chicken nuggets, shrimp chips, and potato chips. It is an ideal piece of equipment for modernizing the production of traditional foods.

Technical Data

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online