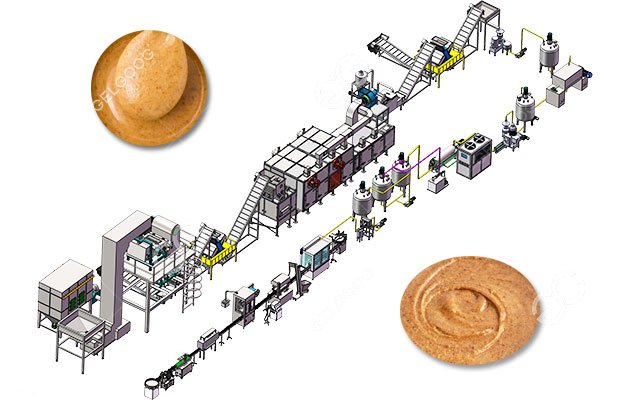

Industrial Hard Biscuit Production Line 100-1200kg/h

Output:100-1200KG/H

Output:100-1200KG/H Voltage:380V

Voltage:380V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

The industrial hard biscuit production line is designed for large-scale production of hard biscuits. It has an hourly capacity of 100-1200kg. The production capacity range is wide and suitable for biscuit factories of different sizes.

In addition to producing hard biscuits, the entire line is also compatible with soda biscuits, crackers and other categories. After adjustment, some equipment can also be used for soft biscuit processing, which has a wide range of applicability.

Features of Hard Biscuit Processing Line

- The molds and parameters can be adjusted quickly, and the styles can be changed easily. For example, when making soda biscuits and hard biscuits, a mold with pinholes is used, and the switch is done in 15 minutes. The thickness can also be freely adjusted from 0.6mm to 10mm. Even if the customer wants to make soft biscuits, it can be quickly replaced.

- The oven determines the color and crispy taste of the hard biscuits, which is very important. It adopts PID automatic constant temperature control, with a hot air circulation system, and independent temperature zones to adjust the surface fire and bottom fire to ensure that the hard biscuits are quickly dehydrated, expanded and shaped.

- The contact surfaces of the dough mixer, biscuit forming machine and other equipment are all made of 304 stainless steel. The corners of the machine are well designed and smooth so that the operator will not be bumped or injured.

- Key equipment of industrial hard biscuit production line is equipped with multiple induction probes. If there are abnormalities such as abnormal current in the dough mixer and deviation of the conveyor belt, the central control screen will immediately pop up a red alarm.

- From dough rolling to hard biscuits being cooled out of the oven, the whole process is stable. For example, a laser thickness gauge is used in the dough rolling stage, and the deviation is automatically corrected if the deviation exceeds 0.5mm; the oven is divided into 4 temperature zones and independently controlled, so that the hard biscuits are evenly colored.

Video of Hard Biscuit Production Process

Core Single-machine Equipment Composition of the Biscuit Plant

- Spiral dough mixer

- Biscuit roller cutter forming machine

- Electric/gas biscuit tunnel oven

- Oil sprayer/sprinkler (salt, sugar, etc.) machine

- Conveying cooling line

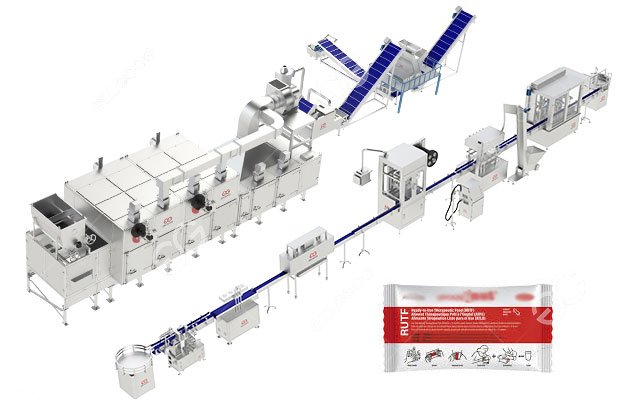

- Automatic packaging machine

Five Reasons for Choosing Industrial Hard Biscuit Production Line

- High cost performance: Under the same production capacity, the machine price is 30% lower than that of European brands.

- Easy maintenance: The production line adopts a modular design, and wearing parts support quick replacement.

- Multiple products on the same line: One set of hard biscuit processing line can produce hard biscuits, soft biscuits, sandwich biscuits, cookies, and other varieties.

- Own factory proof: 5000㎡ biscuit demonstration factory is open for visits, witness the real operation of the same equipment with your own eyes.

- 100+ existing formulas: professional laboratory provides full-process food process services, hundreds of process formulas. Special customization is also supported.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online