Automatic Soft Biscuit Production Line - GELGOOG

Output:100-1000KG/H

Output:100-1000KG/H Voltage:380V

Voltage:380V Power: /

Power: / Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

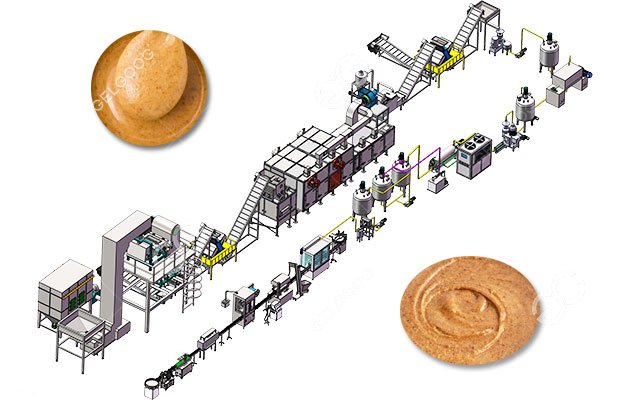

The automatic soft biscuit production line produced by GELGOOG is a multifunctional equipment. It integrates automation and intelligence, and is made of high-quality materials and high-standard processes.

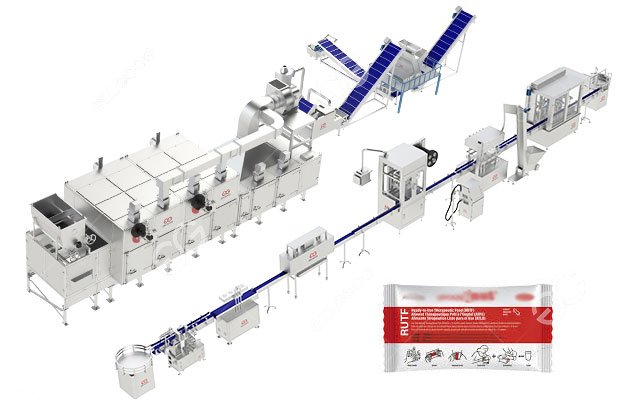

From dough mixing and shaping to baking, cooling and packaging, the entire production process is fully automated. The entire line only requires 3-4 people to monitor the operation without excessive human intervention.

Features of Automatic Soft Biscuit Production Line

- Streamlined from start to finish, our automated system handles everything from raw material prep to packaging with precision. This not only eliminates human error and contamination risks but also ramps up efficiency and trims workforce expenses.

- By replacing different molds, the production line can produce soft biscuits of various shapes and sizes, such as sandwich biscuits, animal biscuits, letter biscuits, etc. Meet the needs of different consumers and the diversified product needs of the market.

- The production line is equipped with an advanced control system. It can accurately control the parameters of each link such as dough mixing time, temperature, molding size, baking temperature and time, ensuring that each batch of biscuits can maintain consistent quality and taste.

- Our product centers on ergonomic design, featuring a user-friendly interface that simplifies operations and maintenance. Its easy-to-clean and maintain structure ensures the equipment stays in top shape for a longer service life.

- The machine uses high-quality alloy rollers, engineering plastic molds and other high-quality parts to ensure that the equipment can still maintain high precision and stability after long-term operation, reducing the equipment failure rate and maintenance costs, and improving production efficiency.

Equipment Application

This automatic soft biscuit production line is tailored for all types of biscuit manufacturers and provides a full range of solutions. In terms of product types, it can handle a variety of flavor combinations, such as cream, chocolate, sea salt, matcha, etc. It can also shape various biscuit shapes, including round, square, animal, cartoon, etc., to meet the needs of different consumer groups in the market.

At the same time, the production line has strong customization capabilities. It can adjust the production process and formula according to the special needs of customers to create unique biscuit products, helping enterprises to stand out in the fierce market competition and accurately grasp the pulse of the market.

Video of Industrial Soft Biscuit Production Line

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online