Fried Bowl Instant Noodle Production Line Price Customized

Output:60000packs/8hrs

Output:60000packs/8hrs Voltage:380 V

Voltage:380 V Power: 22 KW

Power: 22 KW Payment Method: T/T, L/C, Western Union

Payment Method: T/T, L/C, Western Union

Features

Description of Automatic Instant Noodle Machine

This bowl instant noodle production line can produce fried instant noodles, cup noodles, bowl instant noodles, the production process is automated, and the operation is simple. There are a variety of models to meet the needs of different users, and support customization.

The factory has developed different models of cup noodle lines, which can produce 11,000 packs, 30,000 packs, 60,000 packs, 80,000 packs, 100,000 packs, 120,000 packs, 160,000 packs, 200,000 packs of fried instant noodles per hour.

The factory has developed different models of cup noodle lines, which can produce 11,000 packs, 30,000 packs, 60,000 packs, 80,000 packs, 100,000 packs, 120,000 packs, 160,000 packs, 200,000 packs of fried instant noodles per hour.

Bowl Instant Noodles Manufacturing Process

Prepare the flour, water and other ingredients -- Stir and mix the dough -- Dough proofing --Dough pressing and corrugating -- Noodles steaming -- Instant Noodles Cutting -- Spraying seasoning (optional) -- Frying and drying -- Cup noodles cooling -- Put seasoning packet -- Fried noodles packing -- Boxing

Bowl instant noodle processing line produced by advanced technology, with advanced structure, stable performance, reliable quality and low oil content that provide an ideal choice for the investor in fried or non fried instant noodle and other food industry.

Below is a video showing the cup noodle machine production process.

Features of Instant Cup Noodle Production Line

- This automatic instant noodle plant is new generation development which developed by our company based on similar productions from overseas and domestic market.

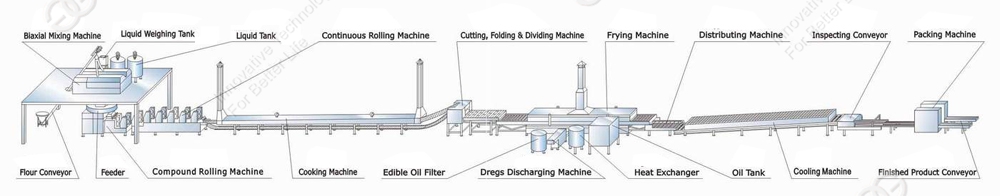

- Main machines of this plant are dough mixer, pressing machine, continuous rolling machine, steaming machine, cutting and folding machine, frying machine, cooling machine, and packing machine.

- Change the cutter and molds, this machine also can produce other shape and sizes of instant noodles.

- The dough mixer has biaxial elliptic blades with two kinds of speed. Curing machine uses double pot technology to guarantee the consistency of dough ripening.

- Convenient loading and unloading of the scraper, pressure can be adjusted by random, no damage to roller. Rolling machine adopts nine pairs of chilled alloy roll.

- Three times of dough rolling, after folding, turn to 90° with continuous rolling, to improve the gluten strength of dough sheet.

Advantages of Fired Noodles Manufacturing Plant

- The operation of whole line is simple and the degree of automation is high. The electrical part adopts digital control and touch screen display.

- Automatic adjustment of dough sheet thickness, no manual operation, automatic dough sheet feeding and tracking.

- Convenient loading and unloading of the bowl instant noodles production line's scraper, pressure can be adjusted by random, no damage to roller.

- Safe production, all parts are made of well-known brand electrics, and the food contact part is made of stainless steel.

Flow Chart of the Instant Noodles Processing Line

Purchase Notice

1. both parties sign a contract and take effect only after the seal is sealed.

2., in order to prevent customers from being cheated, all transactions are based on company account. If there is no public account, the company legal person account is the standard.

3.. After the signing of the contract, the buyer paid 40% deposit, we started to arrange production, after the completion of production, customers come to the inspection machine, the inspection machine no problem again delivery, if the inspection process found problems, first consultation solution, if the customer is not able to meet the requirements, the full refund. If there is no problem for the inspection, pay the end payment and deliver the goods.

4., the equipment produced by the company has 12 months warranty period and no worries after sale. The company always provides vulnerable parts to ensure that the equipment can run normally for a long time.

Technical Data

| Capacity | 60000packs/8h |

| Power | 55kw |

| Voltage | 380v |

| Instant Noodels Size | Customized |

| Equipment length | about 49m |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online