Gelgoog Potato Chips Project Delivery Work In Gabon

2024-10-18 by Lisa

On October 18, 2024, Gelgoog held a grand installation and commissioning briefing and farewell ceremony for the potato chips project in Gabon. The Gelgoog delivery team will set off immediately. The entire delivery cycle is expected to be 15 days. It will provide customers with a full range of services from installation, commissioning to training to ensure the smooth commissioning of the project.

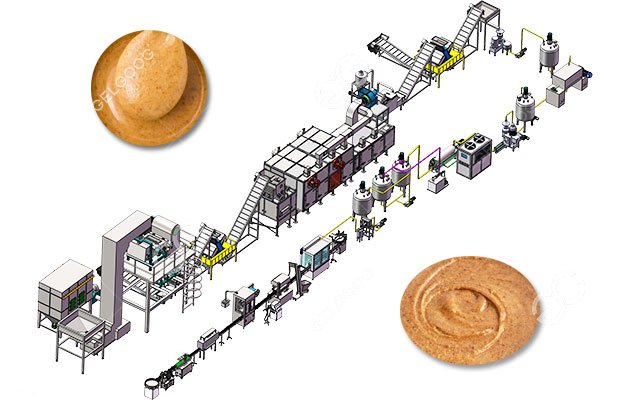

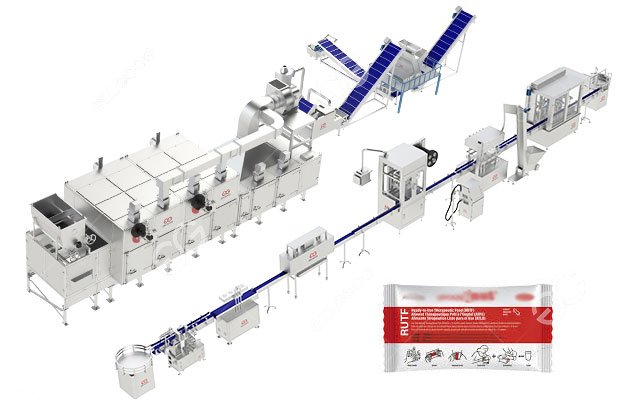

The potato chips project in Gabon covers the complete production process from peeling, slicing, blanching, dehydration, frying, deoiling, seasoning to packaging. The customer's main products are fried potato chips and banana chips. With its rich experience and advanced technology in fried potato chips projects, Gelgoog has tailored a full process solution according to customer needs, further strengthening its advantages in saving fuel and energy, improving efficiency and reducing labor costs.

At the meeting, the project solution engineer, delivery manager, account manager and on-site delivery engineer leader discussed in detail the key nodes and technical difficulties of installation and commissioning, and emphasized the safety precautions and discipline requirements during the installation process. The Gelgoog delivery team promised to strictly abide by the installation specifications, efficiently complete the technical briefing of the potato chips project in Gabon, help customers achieve stable production as soon as possible, and create greater value for them.

Over the years, Gelgoog has always insisted on technological innovation, and has obtained a number of CE certifications, patents and copyrights in the fields of fresh fruit and vegetable processing and frying, and has provided efficient and energy-saving production solutions for many customers around the world. Well-known companies including Unilever and Cargill have given high praise to Gelgoog's products and services. In the future, Gelgoog will continue to be committed to product innovation and service optimization, work hand in hand with customers to jointly create high-quality food processing projects and achieve win-win cooperation!

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык