Features

Introduction:

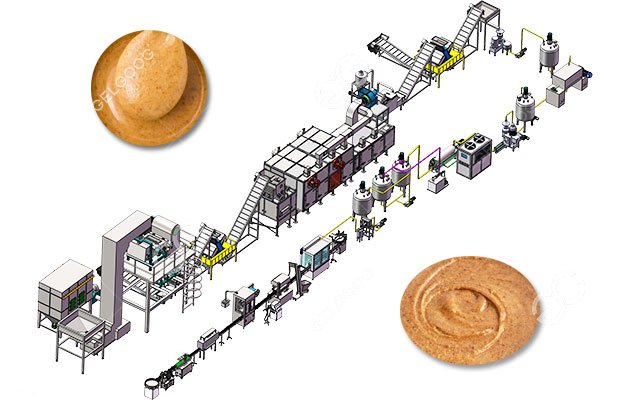

GELGOOG coffee corn processing line is an ideal processing equipment to making coffee corn, coffee buckwheat etc. The whole line including Sugar Cooking Pot, Hot Air Circulating Dryer, Air Flow puffing machine, Automatic Fryer Machine, Flavor Mixer Machine and Automatic Packing Machine. All machine with high quality.

Corn puffing machine can puffing soybean, rice, corn, millet, wheat, buckwheat etc, high efficiency, big output, low energy consumption, easy operation, save and long service life. The puffing machine can use electric heating, natural gas heating and liquefied gas heating, multiple choice. The cooking port is mainly used for candy, rice crisp, beverage, pharmaceutical and other processing; the hot air circulation drying machine for candy, fruit cakes, frozen rice seeds, medicines, etc; the automatic fryer has automatic temperature control system to ensure stable product quality, pneumatic improve the material, the operation more convenient, to facilitate replacement of the mixing port, enabling semi-automated production, various forms of combustion system can adapt to different environments.

The corn flavor of the products can be coffee, cream, sesame, peppery etc, very popular all over the world. The coffee corn production line is economical, practical and popular.

Advantages:

1. The flavor of the products can be coffee, cream, sesame, peppery etc.

1. To save energy: puffing extrusion machine than small releases raw materials saving a third of energy.

2. The products processed by this line have a uniform color and size, good taste.

3. High yield, low energy consumption and high safety

4. Reliable performance, simple construction stable operation, long service life.

5. High automatic, stand-alone machine can be controlled separately, simple operation and easy maintenance

6. The plant is a new generation product developed exclusively in China based on the advanced structure of existing plants from domestic market and abroad.

7. We have approved by CE, ISO and SGS. They all are proves of our high quality.

8. The production line capacity can be choose according to customer special requirements.

Technical Data

| Equipment Name | Power (kw) |

Output (kg/h) |

Dimension (mm) | Quantity |

| GG-600 Sugar Cooking Pot | 32 | 100-300 | 1700*1240*1110 | 1 |

| GG-408 Hot Air Circulating Dryer | 4.8 | 150-200 | 5600*1600*1600 | 1 |

| GG-120 Air Flow puffing machine | 0.75 | 100 | 1800*800*1200 | 2 |

| GG-1200 Automatic Fryer(heat) | 26 | 100-200 | 1600*1600*1500 | 1 |

| GG-680 Flavor Mixer | 1.1 | 150 | 950*580*1200 | 1 |

| GG-100 Automatic Packing Machine | 2.2 | 100-150 | 970*680*1950 | 1 |

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Output:

Output:

Get Price

Get Price Chat Online

Chat Online