300KG/H Stick Noodles Making Machine For Sale in Low Price

Output:

Output: Voltage:

Voltage: Power:

Power:  Payment Method:

Payment Method:

Features

Description of Stick Noodles Making Machine

This equipment is the fully automatic machinery for processing stick noodles in different sizes, low price and the production capacity is large, this stick noodle machine is suitable for large noodle manufacturers.

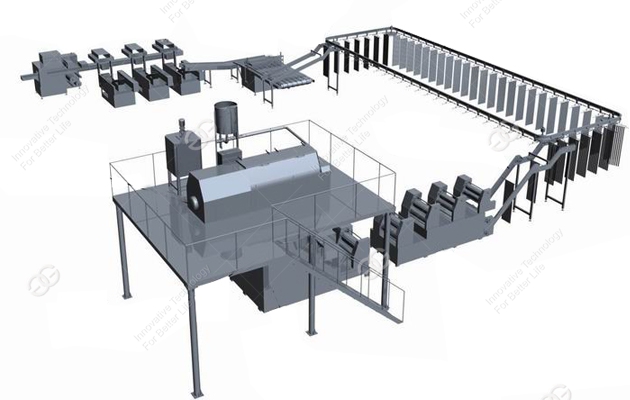

The whole production line consists of dough mixer machine, drying machine, noodles cutting machine, elevator, packaging machine, etc. Each hour can make dry stick noodles of 300 kilograms and even more, also can be customized by customers' requirements.

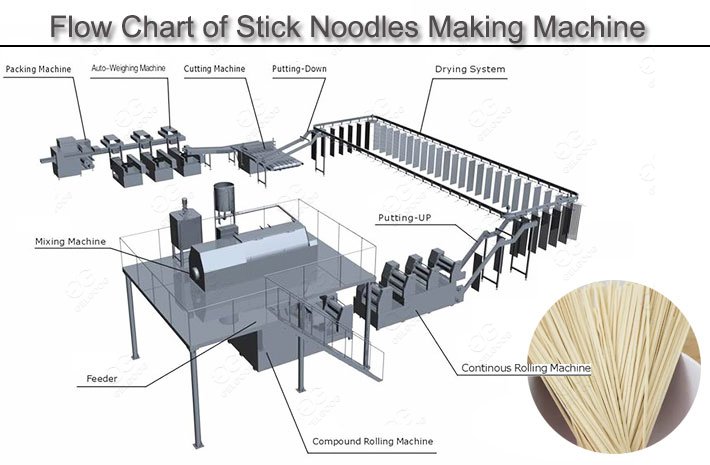

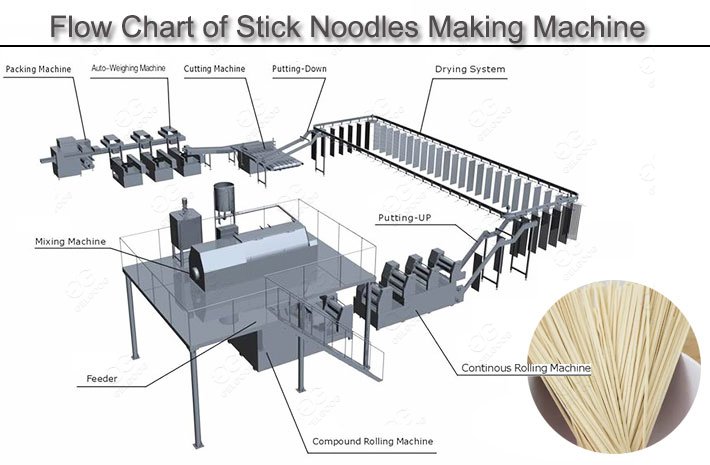

Here is the Flow Chart Of Stick Noodle Making Equipment: Metering salt and water mixing---dough mixing---ripening---calendering---noodles on the shelf---cutting---drying---noodles off the shelf---packaging.

Malaysia Stick Noodle Equipment Working Video

This stick noodles making machine often for sale to Malaysia, India, Japan, America, etc, the equipment has different outputs and can meet different customer needs. If you need stick noodle machine price, please contact us or leave your request. Email: lisa@machinehall.com Skype: jacobyaogelgoog Whatsapp/Wechat/Mobile: +8615515571373.

This equipment is the fully automatic machinery for processing stick noodles in different sizes, low price and the production capacity is large, this stick noodle machine is suitable for large noodle manufacturers.

The whole production line consists of dough mixer machine, drying machine, noodles cutting machine, elevator, packaging machine, etc. Each hour can make dry stick noodles of 300 kilograms and even more, also can be customized by customers' requirements.

Features of Automatic Stick Noodles Making Machine

Types of Noodles Produced by Stick Noodle Machine

Main Parts of Low Price Stick Noodles Making Machine

1. Mixing machine adopts double-rotation design and spray type sprinkler to make flour and water mix more evenly.

2. The cutting knife is made of high-quality carbon steel, which is sharp and wear-resistant, cutting fast and smooth.

3. This stick noodles making machine equipped with high-precision metal detector to prevent harmful substances in food.

4. High degree of automation, dough mixer is equipped with timing discharge device, no manual, mechanical automatic conveying of noodles.

5. The cutter has different specifications, which can produce a variety of stick noodles with different widths.

Types of Noodles Produced by Stick Noodle Machine

Main Parts of Low Price Stick Noodles Making Machine

1. Lifting device: Through automatic feeding system, the raw materials are transported to the metering device in a certain way.

2. Dough mixing: Dough mixing technology includes brine mixing plant, quantitative water supply device and two sets dough mixer.

3. Drying: The noodles into the chamber, the wet noodle can through the returning device continuously and uniformly convey to the curing machine

4. Cutting and packing: Cutting with same size, the finished stick noodles will be transported to the weighing and packing machine through convey.

Here is the Flow Chart Of Stick Noodle Making Equipment: Metering salt and water mixing---dough mixing---ripening---calendering---noodles on the shelf---cutting---drying---noodles off the shelf---packaging.

Malaysia Stick Noodle Equipment Working Video

This stick noodles making machine often for sale to Malaysia, India, Japan, America, etc, the equipment has different outputs and can meet different customer needs. If you need stick noodle machine price, please contact us or leave your request. Email: lisa@machinehall.com Skype: jacobyaogelgoog Whatsapp/Wechat/Mobile: +8615515571373.

Technical Data

| No. | Equipment Name | Model | Parameter |

| 1 | Measure and Feeding Machine | GGYSJ10 | Pump 0.75kw, Volume 110L, with liquid level display, round tank, stainless steel. |

| 2 | Double Shaft and Speed Mixer | GGHMJ200 | Motor power 6.5/8kw, 150kg/batch, manual opening, food contact parts are made of stainless steel and nylon |

| 3 | U Type Dough Ripening Machine | GGXHJ200 | Power 4kw, 200kg/batch, 1600×800×750 Contact part is stainless steel. |

| 4 | Compound and Continuous Dough Rolling Machine | GGMT7-50 |

Slitting width 350mm, power 5.5kw+5.5kw, 7pairs steel roller, machine is steel structure(frequency control), roller diameter, φ180×2, φ240×1, φ180×2, φ162, φ120 |

| 5 | Hanging Stick Supplying Machine | GGGT450 | Power 1.5kw (frequency control), noodle length adjustable, front and rear uniformity adjustable. |

| 6 | Noodle Cutting Tidy Machine | GGZJQ800 | Power 1.1kw |

| 7 | Hanging Rising Machine | GGSJ350 | Power is supplied by Hang Stick Supply Machine, carbon steel. |

| 8 | Chain Plate Drying Machine | GGPHF30 |

Main power 3kw (frequency control), industrial fans 0.75 kw ×13 sets, moisture removal fans, 4 kw×1set(or 0.6kw*6sets), 4 rows rod, length 50m, drying time 4hours. Stainless steel noodle hanging rods 4000pcs. |

| 9 | Sideway Hang Down Machine | GGXJ350 | Power 1.5kw(frequency control), carbon steel. |

| 10 | Automatic Hob Cutting Machine | GGZQM50A | Noodle length adjustable 120~290mm, power 0.8kw. |

| 11 | Electric Control System |

Host to drying room main transmission adopts to frequency control, PLC control. Domestic electrical components, not include cable. |

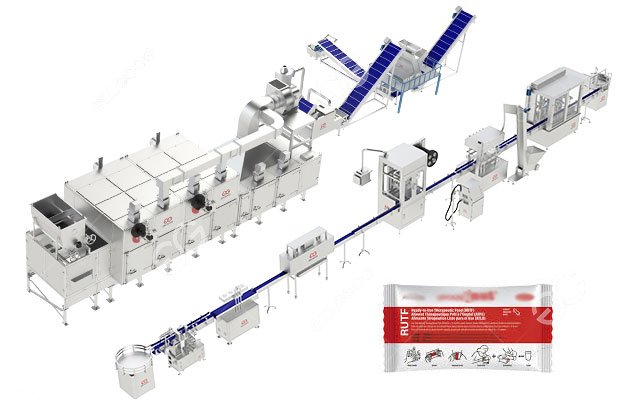

Related Products

Message

Whatsapp:0086-155-1557-1373

Whatsapp:0086-155-1557-1373 Русский язык

Русский язык

Get Price

Get Price Chat Online

Chat Online